What is Pogo Pin, A High-efficient Connectivity Technology with Innovative Spring Loaded Pin Is Critical to Your Success. We Discuss What Benefits Pogo Pin Brings You, and boosts efficiency and cuts costs: proven techniques unveiled. Let’s dive into why Pogo Pins are the go-to option for designers and engineers.

What is Pogo Pin? Pogo Pins, The design of pogo pins provides flexibility during connections, automatically compensating for minor height differences in mating surfaces. Due to their reliability and ability for repeated use, pogo pins are indispensable tools in electronic product testing and development. Additionally, their compact design allows for use in very tight spaces, which is particularly important in modern electronic devices. Let’s know more now!

Introduction of What is Pogo Pin

In the highly competitive field of innovation engineering and electronics manufacturing. Every detail can impact a product’s market performance and a company’s profitability. With technology constantly advancing, choosing the right precision components becomes crucial. Pogo Pins, as efficient spring-loaded connectors, quickly emerged as the top pick for numerous businesses. They can offer outstanding electrical performance and reliable mechanical connections. Significantly reduce production and maintenance costs by streamlining assembly processes.

Basics of What is Pogo Pin

Definition and Design

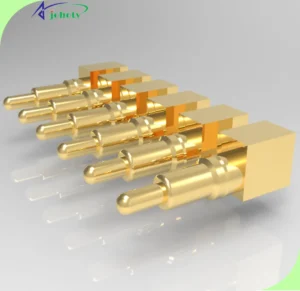

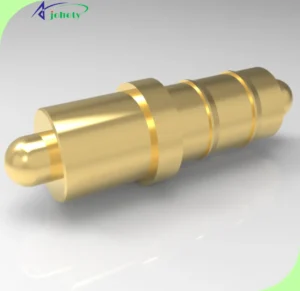

- Pogo Pins are highly reliable connectors widely used to achieve repeatable precise electrical connections, as spring-loaded pins. They comprise three key components: the barrel, spring, and plunger.

- This unique construction enables Pogo Pins to maintain stable electrical contact during continuous compression and release cycles. This makes them ideal for applications with frequent plugging and unplugging needs.

Working Principle

- Pogo Pins operate on a basic mechanical principle. It is an internal spring that provides constant pressure to the movable plunger. This ensures good contact with the mating surface.

- This design can ensure excellent electrical performance with high resistance to vibration and high resistance to shock. Making it an ideal connectivity solution for modern portable and high-vibration environments.

Comparison with Other Connectors

- Compared to traditional pin or socket connectors, Pogo Pins offer several advantages.

- Firstly, their self-cleaning feature reduces maintenance requirements. As it automatically removes contaminants from the contact surface during insertion and extraction.

- Secondly, the compact design of Pogo Pins is for limited space.

- Additionally, due to their outstanding durability and reliability, Pogo Pins are increasingly favored in high-end markets. Such as military and aerospace.

Technical Details and Applications of What is Pogo Pin

Physical Parameters

- Size and Shape: We can customize different dimensions of Pogo Pins, such as diameters and lengths. And how they cater to various device design needs.

- Material: We manufacture high-quality Pogo Pins with premium raw materials, such as stainless steel or brass. These raw materials can provide corrosion resistance and strength.

- Electrical Characteristics: Provide detailed specifications of Pogo Pins’ current and voltage ratings, emphasizing the importance of low contact resistance.

Design Optimization

- Spring Design: Design different types of springs, such as coil springs, and compression springs, and their impact on performance. Especially durability during high-frequency usage.

- Contact Endpoints: Elaborate on how endpoint designs, such as spherical, conical, etc, optimize contact reliability and reduce wear.

Pogo Pin Applications

Electronics

- Mobile Devices: Pogo Pin applications in smartphones and tablets, such as for charging ports or data transmission.

- Wearable Technology: How Pogo Pins make charging for wearable devices more convenient and reliable.

Industrial and Automotive

- Automation Machinery: How Pogo Pins improve machine connectivity reliability and reduce downtime in industrial automation.

- Automotive: Pogo Pin applications in modern cars, including their use in sensors and control systems.

Aerospace and Military

- Satellites and Aircraft: Showcase how Pogo Pins ensure the connectivity reliability of critical communication equipment in extreme environments.

- Military Equipment: How Pogo Pins are used for rapid deployment and high-reliability requirements in military equipment.

Business Advantages of What is Pogo Pin

Cost Efficiency

- Reduced Maintenance Costs: With the self-cleaning feature of Pogo Pins, they effectively decrease maintenance issues and costs caused by poor contact. This self-cleaning action naturally removes tiny particles from the contact surface during insertion and extraction.

- Extended Product Lifespan: The design and high-quality materials of Pogo Pins enable them to maintain excellent performance even under high-frequency usage. Thereby extending the lifespan of the entire device.

Enhanced Production Efficiency

- Streamlined Assembly Process: The simple and reliable design of Pogo Pins accelerates the assembly process, reducing assembly error rates. It is crucial for time and cost management on production lines.

- Support for Modular Design: The compact and modular capabilities of Pogo Pins allow businesses to flexibly design and upgrade their electronic products without extensive redesigning.

Improved Product Reliability and Performance

- Enhanced Connection Stability: In applications requiring frequent mating, such as charging stations and data interfaces. The stable and reliable electrical connection provided by Pogo Pins ensures continuous device performance.

- Adaptation to Harsh Environments: The robust environmental resistance of Pogo Pins, such as temperature and vibration resistance. Makes them excel in extreme applications like aerospace and military fields.

Support for Innovation and Market Adaptability

- Facilitating Technological Innovation: The flexibility and high-performance characteristics of Pogo Pins support businesses in adopting innovative technologies in product design. Such as transferring high-speed data and wireless charging.

- Rapid Market Adaptation: As the market demands more efficient, smaller, and faster devices. The adaptability of Pogo Pins enables businesses to quickly respond to market trends and maintain a competitive edge.

Use Case of What is Pogo Pin

Background:

- Our client is a leading German medical equipment manufacturer. They faced the challenge of improving the reliability of portable diagnostic devices. The devices needed to be frequently connected to various diagnostic modules. However traditional connection systems led to unstable connections due to wear and dust accumulation.

Challenge:

- A connection solution needed to be designed to withstand high-frequency usage while maintaining stable electrical performance. Ensure user safety and hygiene.

Solution:

- Our client ultimately adopted our Pogo Pin technology. It offered an ideal connection solution with its unique self-cleaning ability and long-lasting durability.

Implementation and Results:

- Implementation: We selected high-quality 316L for the Pogo Pins, combined with medical-grade plastic casing. Ensure both reliable contacts and compliance with medical hygiene standards. The design of the Pogo Pins allowed for quick and safe switching between different diagnostic modules.

- Results: By using our Pogo Pins, the device’s connection failure rate decreased by 70%. And, overall operational costs decreased by 30% due to reduced maintenance requirements. Additionally, user satisfaction with the device significantly increased because the reliability of the connections directly improved diagnostic accuracy and speed.

Business Impact:

- By adopting our Pogo Pin technology, the customer enhanced the market competitiveness of their products and strengthened their brand’s industry reputation.

- Furthermore, this technological solution helped the client establish an image of innovation and reliability in the medical equipment market. Attract more business collaborations and customer attention.

Buying Guide of What is Pogo Pin

Basic Parameters

- Size and Shape: Choose Pogo Pin sizes and shapes that fit your device design and space constraints.

- Material Selection: Identify materials best suited for specific application environments. Such as corrosion resistance or high strength, based on different materials like brass or stainless steel.

- Electrical Performance: Select Pogo Pins based on the required current, voltage, and contact impedance.

Special Requirements for Operating Environment

- Environmental Adaptability: Choose Pogo Pins capable of withstanding specific environmental challenges, such as high temperatures, vibrations, or frequent insertions and removals.

- Safety and Certification: Opt for Pogo Pins compliant with ISO and RoHS compliance.

Criteria for Choosing Suppliers

- Quality Assurance: Assess suppliers’ quality control processes and product quality assurance measures.

- Supply Chain Stability: Select suppliers offering stable supply and good inventory management, such as Johoty.

- Technical Support and Customer Service: Ensure suppliers provide strong technical support, especially in product selection and post-sales maintenance.

Procurement Strategies

- Bulk Purchasing: Benefit from cost advantages like discounts and favorable shipping terms through bulk purchases.

- Sample Testing: Test samples before bulk purchases to verify if Pogo Pin performance meets technical specifications and application requirements.

Future Outlook and Technological Upgrades

- Technological Upgrades: Please pay attention to our R&D capabilities to leverage the latest technologies for enhancing your device performance.

- Long-term Collaboration: Establish long-term partnerships with us to ensure your product quality continuity and priority access to technological updates.

Conclusions

Through this discussion, we have thoroughly understood the design principles, technical details, wide-ranging applications, and business advantages of Pogo Pins. Pogo Pins are not just a connectivity solution. They are a key tool driving technological innovation, improving product reliability, and streamlining production processes. Their high durability, outstanding electrical performance, and excellent mechanical stability make Pogo Pins the preferred technology in industries. Such as electronics, automotive, medical, and aerospace.

Choosing our Pogo Pins means your products will enjoy longer lifespans, fewer maintenance needs, and stand out in competitive markets. Their self-cleaning properties and resistance to environmental interference further ensure performance stability and reliability.

Choosing our Pogo Pins means your products will enjoy longer lifespans, fewer maintenance needs, and stand out in competitive markets. Their self-cleaning properties and resistance to environmental interference further ensure performance stability and reliability. We encourage all enterprises seeking to elevate connectivity technology standards to consider integrating Pogo Pins into their product designs. Whether your needs are to enhance production efficiency, reduce operational costs, or simply strengthen your product’s market competitiveness. Our Pogo Pins provide a robust solution.

We encourage all enterprises seeking to elevate connectivity technology standards to consider integrating Pogo Pins into their product designs. Whether your needs are to enhance production efficiency, reduce operational costs, or simply strengthen your product’s market competitiveness. Our Pogo Pins provide a robust solution.