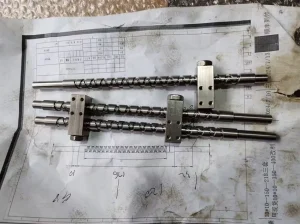

Lead Screw Manufacturing Breakthroughs of 2025! Top 10 Innovations in Materials, Geometry, Automation, Performance for Engineering Precisions!

Introduction: Top 10 Innovations in Ball Screw Manufacturing Technology in 2025

In mechanical transmission and precision engineering, lead screws have long been an indispensable core component. However, in the increasingly complex and diverse industrial environment, are engineers tired of the bottlenecks of traditional lead screws in high load, high precision, wear resistance, and long life? Are you also looking for more efficient and intelligent transmission solutions when faced with the demand for automation upgrades and intelligent transformations?

In 2025, the lead screw manufacturing will usher in various technological innovations. The introduction of innovative technologies and breakthrough materials has overturned the limitations of traditional craftsmanship. Bringing the lead screw to new heights in lightweight, wear resistance, precision control, and adaptability to extreme working conditions. So, how were these breakthroughs achieved? What new possibilities will it bring to engineering applications?

In this era of increasingly fierce competition in cutting-edge technology, which innovations are worth investing in and applying? How to quickly identify and utilize the latest technology in a project to gain market advantage? If you also have similar questions, in this blog, Johoty will take you to uncover the answers one by one.

Here, Johoty show you top 10 innovative technologies for lead screw manufacturing in 2025. They include breakthroughs in materials science, optimization of geometric structures, upgrading of manufacturing processes, integration of intelligent technologies, and improvement of environmental adaptability. Not only does it help engineers make more forward-looking judgments in technology selection, but it also enables them to quickly find solutions that are in line with future trends. Whether you are a mechanical design engineer, automation expert, or equipment manufacturer, these technological innovations will have a profound impact on your work.

Read: High Performance Lead Screws

Top 10 Lead Screw Manufacturing Innovations

Breakthrough in Materials Science: Carbon Fiber Composite Screw, Balancing Lightweight and High Strength

The ultimate balance between lightweight and high-strength

Compared to traditional steel screws, carbon fiber composite screws can reduce weight by up to 70%, achieving lightweight design without sacrificing strength. It effectively reduces inertia and energy consumption, and improves response speed in aerospace, robotics, and automation equipment.

Super strong torsional rigidity and fatigue resistance performance

Traditional metal screws are prone to twisting and deformation during high-speed operation, while the multi-layer woven structure of carbon fiber and resin matrix effectively enhance torsional rigidity. It can ensure stability and durability under high-precision transfer. Under continuous high load operation, carbon fiber composite screws exhibit excellent fatigue life. Reduce maintenance frequency and downtime, and lower overall costs in industrial applications.

High temperature curing molding technology

Adopting advanced resin curing and hot pressing molding processes, the carbon fiber layer can be highly integrated with the shape of the screw thread. Significantly improve surface smoothness and machining accuracy, reduce friction coefficient, and enhance transfer efficiency.

Nanocomposite reinforcement technology

By adding graphene nanoreinforcements to the matrix material, carbon fiber composite screws exhibit superior wear resistance and thermal stability. It can ensure long-term operation under complex loads and high temperatures.

Read: High Performance Threaded Rods

Breakthrough in Materials Science: Nanocoating Process, Durable Wear Resistance and Low Friction Coefficient

Durable wear resistance: Nano coatings effectively resist friction and corrosion by forming a dense and uniform protective film on the surface of the lead screw. Compared to traditional coatings, the nanoscale particle arrangement significantly increases surface hardness, thereby extending the service life of the lead screw.

Ultra low friction coefficient: The new nano material achieves low friction characteristics through molecular level regulation, reducing the energy loss of the lead screw during motion. This is particularly important for high-speed and high-precision transmission equipment, as it can significantly reduce the accumulation of heat and energy consumption of the equipment.

Self lubricating properties: Some nano coatings use MoS ₂ or DLC self-lubricating materials, further reducing the friction coefficient and eliminating the hassle of frequent lubrication and maintenance.

Geometric structure optimization of Lead Screw Manufacturing for precision and efficiency

Variable pitch ball screw, adaptive dynamic load

Variable pitch lead screw refers to a screw design where the pitch dynamically adjusts with position. Design innovation lies in the fact that by optimizing pitch variation. Friction and noise can be effectively reduced while improving transfer efficiency.

Friction can be adjusted under different load conditions to reduce energy loss significantly and greatly improve overall efficiency. By finely controlling pitch variation, lead screw can provide more consistent performance in high-precision applications. Different pitch can be used for different applications and load requirements to ensure optimal mechanical performance.

Adaptive dynamic load technology ensures lead screw always operates at its optimal working state by monitoring and adjusting load conditions. As the load changes, the system can adjust load distribution of lead screw to ensure stable and efficient transfer. Adaptive load technology enables the screw to maintain a longer working life under high load, avoiding faults caused by excessive wear or overload. By optimizing load and power transfer efficiency, adaptive systems can reduce various energy consumptions significantly and improve system performance.

Lead Screw Manufacturing in Low Noise Double Thread Design with Accuracy and Efficiency

Double thread design

Although traditional single thread design is effective, it is prone to generate significant noise and friction during long-term operation. The double threaded design uses two threads working simultaneously, reducing friction coefficient through precise fitting, thereby significantly reducing frictional heat and noise. This design optimization can improve accuracy of lead screw manufacturing, making motion more stable and quieter.

Noise control

In medical equipment and semiconductor manufacturing equipment that require high precision and low vibration, noise control is a very important technology. Double thread design achieves a more uniform force distribution through geometric optimization, reducing the impact force during each thread engagement. Johoty’s lead screw manufacturing, It can make your device quieter and more stable during operation.

Structural optimization

In geometric structure, using heat treatment technology and advanced materials, double threaded design can provide higher load capacity. And, its durability and wear resistance can also be greatly improved. By precisely controlling thread microstructure, higher machining accuracy and stability can be maintained in lead screw manufacturing. This can reduce error rate and improve the efficiency of lead screw and your equipment.

Lead Screw Manufacturing Innovations’ efficient and precise additive manufacturing helps customize ball screws

The advantages of additive manufacturing technology

Additive manufacturing technology has played an important role in lead screw manufacturing. By stacking materials, additive manufacturing can precisely control geometric shape and internal structure of lead screw. It can significantly improve accuracy and stability of lead screw. Compared with traditional manufacturing, this method can reduce errors in complex machining. It can effectively save expensive raw materials and engineers’ time costs.

Implementation of customized design

Johoty’s additive manufacturing makes customization in lead screw manufacturing easier. Through digital design, engineers can customize the size, thread type, material, and structure of lead screws. For complex or unique applications, additive manufacturing technology can provide more stable, flexible, and efficient solutions. Meet the precision and efficiency requirements in aerospace, medical equipment, and high-end precision machinery.

Efficient and precise manufacturing process

Additive manufacturing not only demonstrates advantages in customization, but its efficiency is also reflected in rapid prototyping and small batch production. Through this process, manufacturing cycle of lead screw is significantly shortened. It can also complete trial production and optimization of complex structures in shortest possible time. Additive manufacturing can also achieve higher surface quality and geometric accuracy during production process. In subsequent processing, it can greatly reduce various demands.

Lead Screw Manufacturing Innovations achieves real-time monitoring and fault prediction through digital twins

Application of digital twin technology:

Connect virtual replicas of physical entities with real-time data to form a real-time updated model. In lead screw manufacturing, digital twins can monitor the production process and usage status of ball screws in real-time. Through digital synchronization with physical devices, engineers can instantly obtain information about materials, processing accuracy, temperature changes, etc., providing support for decision-making.

Real time monitoring and precise analysis:

Digital twins provide powerful data support for real-time monitoring in lead screw manufacturing. By continuously tracking the status of the production line, digital twins can detect any abnormal changes in real time. It can help engineers accurately analyze potential production issues. It can provide detailed data on the small errors in thread processing and the operating status of the equipment, ensuring each connection accuracy.

Fault prediction and preventive maintenance:

It can monitor production status in real-time and predict faults based on data analysis. By comparing historical and real-time data, digital twins can predict the potential risk of equipment failure. Identify trends of wear or loss of accuracy in advance. This type of fault prediction can help engineers perform preventive maintenance on schedule, reducing downtime.

Maintenance free self-lubricating ball screw for Lead Screw Manufacturing Innovations

Application of self-lubricating technology:

Self lubricating ball screws can operate efficiently without additional lubricating oil through special materials and lubricants. In lead screw manufacturing, adopting a self-lubricating design can significantly reduce the dependence on external lubrication. Ball screws can maintain smooth motion and low friction during long-term operation. This technology not only reduces the use of traditional lubricants and pollution, but also effectively extends the service life of equipment.

Maintenance free design and intelligent management:

Maintenance free operation is another major advantage of self-lubricating ball screws. In traditional ball screws, regularly adding lubricating oil is an important part of the maintenance process. And self-lubricating design eliminates this need through intelligent material and structural design. Compared with traditional systems, maintenance free ball screws can significantly reduce maintenance workload. It can significantly reduce client’s maintenance costs and improve work efficiency. In automated production lines, this maintenance free design can also reduce the frequency of human intervention and improve OEE, overall automation level, and efficiency of production line.

Efficient and stable performance improvement:

Self lubricating ball screws can further optimize the accuracy and stability of ball screws in lead screw manufacturing. By precisely controlling lubrication performance, self-lubricating design can reduce friction. It can also reduce equipment wear caused by lubricant deterioration or lack of lubrication. Efficient and stable performance, self-lubricating ball screws perform well in medical equipment, aerospace, and precision machinery.

Intelligent adjustment servo control for precise response to dynamic demands in Lead Screw Manufacturing Innovations

Intelligent servo control system:

With intelligent adjustment servo control technology, ball screws can adjust operating parameters in real-time in lead screw manufacturing. This can accurately respond to dynamic load changes. Servo control system can effectively monitor and adjust ball screw speed, torque, and position through feedback. Ensure high precision and efficiency can be maintained under different working conditions. This intelligent control greatly improves the response speed and flexibility of the system. The equipment can operate stably in rapidly changing production environments.

Accurately responding to dynamic demands:

Traditional ball screw systems rely on fixed mechanical design and manual adjustment, and cannot respond quickly to changes in load. Introducing intelligent adjustment servo control, ball screw in lead screw manufacturing can automatically adjust working parameters. It can quickly respond to various changes operating conditions and in load. This technology is suitable for robots, 3D printing, precision machinery, automated production lines with high precision and flexibility.

Automation and efficiency improvement:

Intelligent adjustment servo control can improve accuracy and achieve high automation in lead screw manufacturing. By combining with sensors, feedback systems, and control algorithms, servo control systems can monitor and adjust every action in real-time. Reduced human intervention and lowered system failure rate. Based on automatic adjustment capability, the production process is more efficient. It can complete adjustments and continue to operate in short time, ensuring efficiency and stability of production line.

Lead Screw Manufacturing Innovations’ low temperature frost resistant screw with stable output under extreme cold conditions

Advanced materials science of high toughness low-temperature alloys: using high toughness alloys that have undergone deep low-temperature treatment. Ensure stable operation of equipment in the automated machinery of the North and South Pole research stations. The screw can still maintain high strength and impact resistance at temperatures ranging from -60℃ to -150℃, ensuring motion stability.

Cold resistant and anti freezing grease efficient lubrication system: Specially developed anti freezing grease can maintain excellent fluidity and adhesion performance. It can reduce friction coefficient significantly and prevent freezing cracking. Maintain smooth movement of the guide rail and push rod in high-altitude and low-temperature environments.

Precision manufacturing process for surface wear-resistant and antifreeze coatings: maintaining precise control of robotic arms and instrument platforms in deep-sea cold and high-pressure environments. Innovative wear-resistant and antifreeze coatings can effectively prevent ice crystal accumulation. To avoid sudden increase in friction and prolong lead screw lifespan.

Lead Screw Manufacturing Innovations’ high-temperature resistant ball screw that meets extreme environmental requirements

High Heat Resistant Material Technology: Application of Ultra High Temperature Alloys

The high-temperature resistant ball screw is made of ultra-high temperature alloy material, which can maintain its mechanical properties and structural stability in environments up to 600℃. In metallurgical equipment and high-temperature furnace control systems, high-temperature resistant ball screws can resist high-temperature oxidation and continuously output stable power. Compared to traditional materials, lead screws have higher resistance to thermal fatigue and control of thermal expansion coefficient. This ensures precise transmission of the screw at high temperatures.

Thermal stable lubrication technology: anti thermal decomposition lubricating grease

In high-temperature environments, conventional lubricating grease is prone to decomposition and failure. For this purpose, special heat-resistant grease is used to maintain low friction and high lubrication performance in high temperature environments. Extend the service life of ball screws to avoid mechanical jamming and loss of accuracy caused by lubrication failure. In spacecraft and propulsion systems, high-temperature resistant ball screws can maintain precise motion under conditions of rapid heating.

Advanced thermal expansion compensation design

Through the thermal expansion compensation structure, the ball screw can automatically adjust the axial deformation caused by temperature differences. In geothermal drilling and oil and gas exploration, the screw system must withstand high temperatures and severe temperature differences. High temperature resistant ball screws can exhibit high performance due to their heat and wear resistance characteristics. This ensures high accuracy and stability even in complex temperature fluctuation environments.

Conclusion

In 2025, top 10 innovative technologies in lead screw manufacturing are accelerating high-precision, durable, and intelligent development of mechanical engineering. These new types of lead screws can demonstrate reliability, long lifespan, and high performance in extreme environments. It enables engineers to achieve unprecedented technological breakthroughs in various applications.

In constantly changing and increasingly complex industrial demands, choosing the right lead screw is the key to improving productivity. It is also core competitiveness of future technological layout. As a leading lead screw manufacturer, Johoty is committed to using 10 cutting-edge technologies in lead screw manufacturing. Johoty always provide you with various high-quality and highly reliable customized solutions. Contact Johoty immediately to ensure your device keeps excellent performance in extreme environments!