Looking for Best Zero Backlash Lead Screw? Cover Key Technical Preloaded, Ball, Planetary Roller Screws. Help Engineer Match Johoty Solutions.

Introduction: Why is Zero Backlash of Lead Screw so important?

Backlash is a key factor affecting positioning accuracy, repeatability, and system stability in precision motion control and automation applications. Have you ever encountered positioning errors, vibrations, or mechanical looseness caused by return clearances? These issues always affect equipment performance, drop production efficiency, and even bring mechanical failures.

If your design requires high-precision, seamless linear motion, then choosing the appropriate lead screw with zero backlash is crucial. But there are many types of lead screws on the market, how to choose lead screw that truly meets high-performance requirements?

This article will show you core concepts and key influences of zero backlash, and guide you on how to choose the most suitable lead screw. Johoty ensures that your device always maintains precise and error-free linear motion. If you are looking for the best lead screw solution from Johoty, this guide will help you make the wisest choice!

Key factors affecting Zero Backlash Performance of Lead screw

Nut Preload Design

Why is it important? Preload design is main means of eliminating backlash. The clearance of the Lead screw transfer system usually comes from fitting error between the nut and the screw. By increasing the appropriate preload force, the gap can be eliminated, thereby achieving zero backlash.

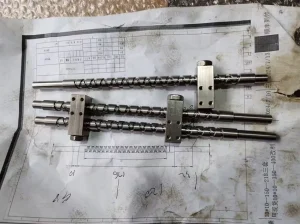

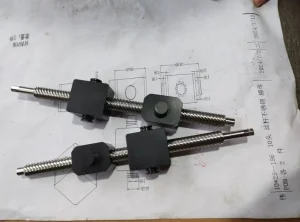

Johoty has advanced pre tightening design solutions that provide high-precision, high rigidity lead screw solutions to ensure zero backlash. Two nuts are used for pre tightening, and axial pre tightening force is applied through springs or mechanical means to eliminate gaps. Utilizing adjustable design split nuts to precisely adjust clearances, suitable for low load, high-precision applications. Using special materials and structural design for self-locking nuts, the nuts automatically adjust to eliminate gaps when subjected to force.

Nut material and friction characteristics

The material of the nut directly affects the friction coefficient, wear resistance, and temperature stability. If the friction coefficient is too high or the wear resistance is insufficient, long-term use will lead to an increase in clearance and affect the accuracy of the system.

Johoty uses customized high-performance composite materials to ensure long-term stability and avoid increased gaps caused by material wear. POM、PTFE、PEEK, It has low friction and self-lubricating characteristics, suitable for low to medium load applications. High wear resistant bronze or brass, but requires lubrication and maintenance, suitable for high load scenarios. Johoty provides optimized formulations of composite materials that combine the advantages of low friction, wear resistance, and low noise, achieving long-term zero backlash.

Lead screw Accuracy & Straightness

The manufacturing accuracy of the screw determines the smoothness of the system’s motion and the accuracy of repeated positioning. If there are straightness errors and pitch errors in the Lead screw, it may cause an increase in backlash and even affect the rigidity of the overall motion system.

By adopting high-precision CNC machining and grinding technology, Johoty can ensure that the Lead screw has extremely high screw precision, minimizing the backlash to the greatest extent possible. Johoty provides high-precision lead screws with a lead error of ± 0.01mm/300mm, ensuring high-precision positioning. Adopting advanced CNC machining technology to ensure straightness error is less than 0.03mm/m, avoiding gap problems caused by screw bending. High quality surface treatment enhances surface finish, reduces friction, improves durability, and avoids increased gaps caused by long-term use.

Axial Rigidity

Why is it important? A lead screw with insufficient rigidity will undergo elastic deformation during high load or high-speed motion, resulting in an increase in the backlash of the system and affecting accuracy.

Johoty uses high-strength materials and optimized design to ensure excellent axial rigidity of the Lead screw, effectively avoiding backlash issues caused by deformation. Johoty adopts an optimized design of Diameter to Length Ratio to ensure high rigidity for both short and long stroke applications. We provide optimized pitch design and thread angle to ensure zero backlash during high-speed motion. Meanwhile, our lead screw can be matched with high rigidity end support stiffness bearings to ensure low deformation and high stability.

Lubrication & Wear Resistance

The job of a lead screw is to constantly rub, and improper lubrication or rapid wear can gradually increase the gap between the nut and the screw, causing the system to lose its zero backlash characteristic.

Johoty has advanced lubrication and protection technology to ensure long-term zero backlash, reduce maintenance requirements, and improve reliability. We provide low friction composite nuts to reduce reliance on lubricants and lower maintenance costs. Can be paired with a micro lubrication system to reduce friction losses and extend lifespan. At the same time, we adopt an anti-pollution design with a sealed dustproof structure to prevent foreign objects from entering and increasing the gap.

Operating Conditions

Lead screw operates in different environments and may be affected by factors such as temperature changes, humidity, dust, etc., resulting in changes in gap.

Johoty has professional solutions for various environments to ensure that the Lead screw maintains zero backlash performance under any operating conditions. We provide high-temperature resistant composite nuts to avoid gap changes caused by thermal expansion. The Lead screw has undergone special surface treatment to ensure zero backlash even at low temperatures/humidity. Provide sealed dustproof nuts suitable for dust/polluted environments, reducing foreign object interference.

How to choose a Lead screw to achieve Zero Backlash Performance?

Determine your application requirements

Before choosing a lead screw, it is necessary to first clarify your applications, as different systems have different requirements for zero backlash. Johoty provides customized lead screw solutions for different applications to ensure they meet the needs of engineers. We will choose 5-axis CNC or 6-axis CNC, which has high repeatability and can provide crucial micrometer level error control for your customized lead screws. At the same time, we need to ensure seamless transfer during high-speed motion to avoid commutation errors. For precision medical instruments, ultra-low friction, low noise, and long-term use without gaps are definitely required.

Choose the appropriate Lead screw structure

Different types of lead screw structures perform differently in controlling the return gap. Johoty provides optimized lead screw solutions for different application scenarios to ensure that your system achieves zero backlash.

Double nut preload, It is suitable for extremely high precision requirements, applying axial preload force through two nuts to completely eliminate backlash. Suitable for high-precision equipment such as CNC machine tools and semiconductor manufacturing. Johoty offers a high rigidity double nut design to ensure long-term stability without backlash.

Anti batch Nut is a cost-effective solution made of polymer materials and utilizes an elastic structure to automatically adjust the gap. Suitable for automation equipment with moderate load and long-term operation. Johoty’s low friction and wear-resistant material design can achieve long-term zero backlash.

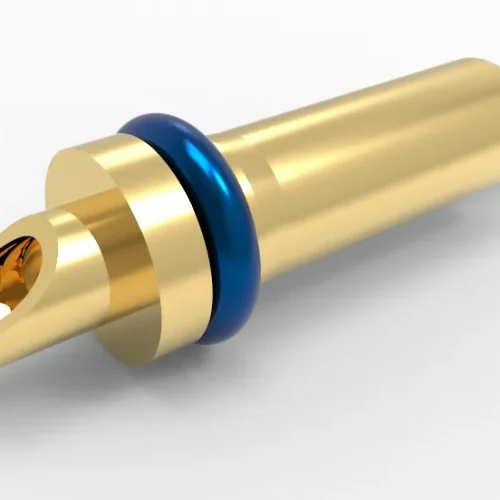

Preloaded Single Nut, Compact structure, ensuring low backlash through precision machining. Suitable for medical instruments, precision measuring equipment, and scenarios that require low friction and low noise. Johoty adopts high-precision CNC grinding technology to ensure the lowest gap error.

Choose high-precision lead screw to reduce inherent errors

The manufacturing accuracy of the lead screw itself directly affects the control ability of the backlash. Choosing Johoty’s high-precision lead screws can significantly reduce errors and achieve a more stable zero return gap.

Johoty Lead screw adopts high-precision CNC machining and grinding technology to ensure that each screw meets ultra-high precision requirements, allowing your system to truly achieve Zero Backlash. Lead accuracy: Johoty provides high-precision lead screws with a tolerance of ± 0.01mm/300mm, ensuring precise and error free movement. Straightness: The high-precision grinding process ensures an error of less than 0.03mm/m, avoiding additional gaps caused by screw bending. Surface Finish: Ultra fine polishing treatment reduces friction, improves service life, and prevents gap enlargement.

Choose the appropriate nut material and friction features

The material and friction characteristics of the nut directly determine the stability of the backlash. Johoty combines high-performance materials with precision manufacturing to ensure that the lead screw has long-term stable Zero Backlash Performance.

Self lubricating polymer, Johoty uses PTFE/PEEK composite materials to reduce friction, improve wear resistance, and ensure zero backlash stability. Suitable for medical instruments and precision automation, ensuring long-term low noise and low wear. Bronze/brass nuts ensure longer lifespan and minimal gap variation. Suitable for industrial machinery with high load transfer.

Choose an optimized support system to reduce deformation errors

The installation method and support system of the lead screw can also affect the control of the backlash. Johoty adopts a high rigidity support system to ensure that the lead screw can maintain zero backlash even during high-speed and high load operation. Provide optimized support components to ensure optimal performance.

End Support Stiffness, Low rigidity supports are prone to deformation under load, affecting gap control. We can provide high rigidity bearing support units to ensure that the lead screw does not deform during high-speed operation. Axial load optimization, By optimizing the pitch and tooth profile angle, ensure that the system can maintain Zero Backlash under different loads. Excessive axial load can affect the pre tightening effect and lead to an increase in clearance.

Choose efficient lubrication and sealing solutions to extend service life

Improper lubrication can accelerate wear and gradually increase the gap. Johoty provides intelligent lubrication and sealing protection to ensure that the lead screw maintains Zero Backlash for a long time.

Optimized lubrication, adopting micro lubrication technology to minimize friction while extending lifespan. Provide efficient lubrication solutions suitable for high-speed and long-life applications. Sealing & contamination protection, Prevent dust and impurities from entering, and prevent wear from increasing gaps. Adopting a highly sealed protective cover design to ensure long-term stable operation.

How does Johoty Lead screw achieve true Zero Backlash?

Double nut pre tightening system, the core technology for eliminating gaps

Johoty adopts a unique dual nut pre tightening design, where two nuts apply a constant pre tightening force through precision machined springs or washers, ensuring no gap between the screw and nut.

This design not only eliminates axial and radial clearances, but also maintains stable zero backlash performance under high loads. In CNC machines, Johoty’s lead screw can maintain a repeat positioning accuracy of ± 0.01mm during high-speed reciprocating motion, significantly improving machining quality.

A German precision instrument manufacturer will use Johoty’s double nut pre tightened lead screw in 2023. The positioning accuracy of the customer’s optical detection equipment has been improved by 30%. Customer feedback: This is the most stable and cost-effective transmission system they have ever seen.

Precision grinding process, micrometer level manufacturing accuracy

The screw and nut adopt high-precision grinding technology to ensure the smoothness of the thread surface Ra≤0.4μm and the geometric accuracy of the error ≤5μm.

Precision grinding can reduce friction and wear, significantly reduce operating noise, and extend service life. Our lead screw can maintain zero backlash for up to 10,000 hours of use. It is commonly used in semiconductor manufacturing equipment, and its performance and effectiveness can satisfy customers.

A US semiconductor equipment manufacturer stated after testing Johoty’s lead screw that its accuracy and durability completely exceeded our expectations, helping us reduce maintenance costs by 20%.

Elastic deformation compensation technology, dynamically adapting to load changes

An elastic deformation compensation structure is designed inside the nut, which absorbs small displacements caused by temperature changes or load fluctuations through high-performance engineering plastics or elastic alloys.

This design can automatically adjust under dynamic loads, ensuring zero backlash performance is not affected by external conditions. It can maintain stable positioning accuracy in an environment with a temperature change of ±10°C, making it suitable for automated production lines.

After testing our lead screw in a high-temperature environment, an Italian automotive parts manufacturer found that its performance is completely unaffected by temperature. The customer praised this as a true industrial grade solution.

High rigidity materials provide protection against extreme loads

We choose high-strength alloy steel SCM440 as the screw material and use special Nitriding or Chrome plating to enhance wear & corrosion resistance.

High rigidity material ensures lead screw stability under extreme loads. In heavy-duty robotic arms, our lead screw can withstand axial loads exceeding 10,000N while maintaining zero backlash.

A French industrial robot manufacturer has increased load capacity of its robotic arm by 15% after using Johoty’s lead screw. The customer sincerely replied to Johoty that this is the most reliable transfer component we have ever seen.

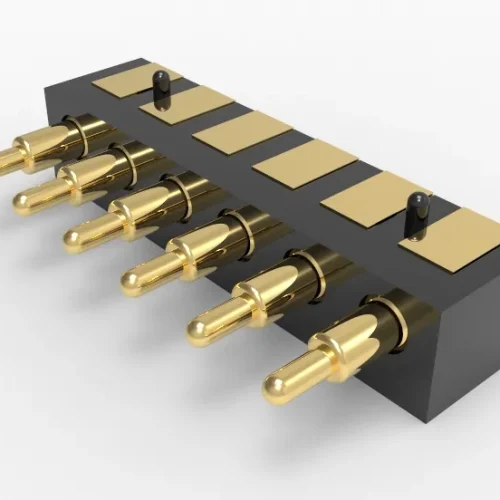

Intelligent preload adjustment system, real-time optimization technology

Real time monitoring of preload through built-in sensors, and automatic adjustment of nut position using micro motors. The intelligent preload adjustment system we have developed can ensure preload is always in the optimal state.

It can reduce manual maintenance for improving system adaptability. In aerospace equipment, it can automatically adjust under different operating conditions to ensure zero backlash performance.

A British aerospace equipment manufacturer tested our intelligent lead screw. The subsequent engineering verification, small-scale trial production, and large-scale production performance testing have been hailed by customers as a revolutionary breakthrough in transfer technology.

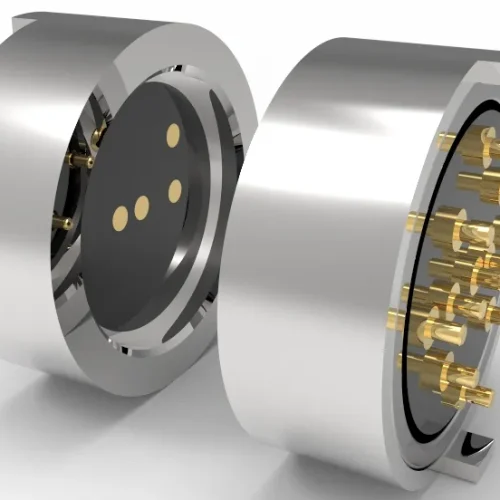

Modular design, quick installation and maintenance

Johoty’s lead screw’s modular design allows for quick disassembly and replacement of nuts, screws, and bearing seats.

Modular design significantly reduces installation and maintenance time, and can lower downtime costs. In food packaging equipment, Johoty’s lead screw can be replaced within 30 minutes, while traditional products require more than 2 hours.

German food packaging equipment manufacturers have used our modular lead screw, which has increased equipment maintenance efficiency by 40%. Customer also sent emails this improved our packaging output significantly.

Strict quality control ensures entire process from raw materials identification to finished product inspections.

From raw material procurement and IQC control to lead screw delivery, Johoty always passes strict quality testing. Our testing includes material composition analysis, dimensional accuracy testing, dynamic performance testing, etc.

23 strict quality controls ensure reliability and consistency of each set of lead screws. Before leaving Johoty, a 100 hour fault free operation test is required to ensure performance meets customer requirements.

After receiving the lead screw from Johoty, a Swiss precision instrument manufacturer found that its qualification rate was as high as 99.99%. The customer WhatsApp said Johoty is the most reliable supplier they have worked with.

Conclusion: Precise selection, optimized performance, let Johoty help you

In precision motion control applications, eliminating zero backlash is the key to improving system rigidity, accuracy, and long-term stability. Through in-depth analysis in this article, Johoty has gained a clear understanding of how to choose the appropriate ball screw or trapezoidal screw to meet different application requirements. However, the real challenge lies in finding high-quality, precision manufactured, and rigorously quality controlled lead screws. This ensures your outstanding performance in practical applications.

Johoty provides industry-leading Zero Backlash solutions to engineers worldwide through ultra precision CNC manufacturing processes, strict 23 quality standards, and customized solutions. Our lead screw is made of high-grade stainless steel and undergoes strict rolling, grinding, and coating treatment. It ensures the lowest friction, highest precision, and longest lifespan. Automation, robotics, medical equipment, high-precision CNC equipment, Johoty can provide customized lead screw solutions to make your designs more competitive.

Contact Johoty’s CFT team now to help you accurately match the most suitable lead screw solution! Johoty, Help you achieve true Zero Backlash performance and achieve higher precision. Consult Johoty immediately for customized lead screw solutions!