Show the best spring loaded electrical connectors for engineers. Expert insights on features, performance, and model selections in modern designs

Introduction:

Choosing the best spring loaded electrical connectors is crucial in your electronic designs. Johoty’s spring loaded connectors can perfectly meet engineers’ expectations regarding features, performance, model selection, reliability, and installation convenience. Read this blog to understand why these pogo pin connectors are ideal for your project. How does Johoty ensure your designs are efficient, safe, and worry-free?

Technical Features for Spring Loaded Electrical Connectors

Excellent conductivity performance

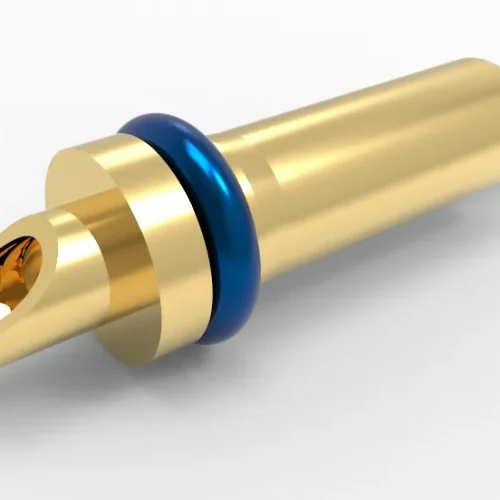

Low contact resistance: Johoty uses brass, beryllium copper, tellurium copper, copper alloys, or stainless steel to design pogo pins, achieving impedance as low as 15mΩ. Usually, we will coat these spring loaded pins with gold, silver, nickel, ruthenium, palladium, rhodium, platinum, as well as composite electroplating suitable for specific environments. We can significantly reduce the resistance of pogo pins and efficiently transmit current and signals.

Wide current range: Current is a key parameter for spring loaded electrical connectors. The implementation of current requires low contact resistance. Customers often request a current ranging from 0.1A to 50A, combined with Johoty’s ability to achieve up to 250V voltage, it is perfect! This pogo pin connector is fully compatible with your signal transfer and high-power power supply.

High frequency compatibility: Johoty’s spring loaded electrical connectors can support high-frequency signal transfer, helping you achieve 5Gbps data transfer rate and 5GHz signal frequency. Low insertion and return loss can effectively reduce signal loss and interference. Our spring loaded electrical connectors are suitable for high signal integrity and low EMI.

High mechanical performance

Precision design: high-precision spring loading, stable electrical contact in dynamic and vibration situations. ±0.01mm minimal tolerance, constant contact pressure, minimizing poor contact to the greatest extent possible. The pogo pin diameter can reach 0.5mm, and miniaturized design supports high-density, multi pin connections. The compact structure provides powerful performance in limited space, suitable for applications involving high-frequency signal transfer, data integrity, and low EMI.

Stability of spring structure: The core of spring loaded electrical connectors lies in high elasticity and durability of the spring, which remains uniform and stable after long-term use. Effectively resist the effects of vibration, impact, and temperature changes on contact pressure. Johoty often uses piano steel, stainless steel to design springs, gold plating, palladium, platinum, etc. to reduce the risk of wear and corrosion. This spring loaded pin ensures low contact resistance and high reliability in high-frequency and high-power transfer. Johoty’s precision springs ensure even contact force for spring loaded electrical connectors. They can adapt to dynamic displacement and multi angle connections while preventing wear and tear.

Long cycle life: Conventional spring loaded electrical connectors are designed to support a lifespan of ≥ 10,000. Johoty can design a high-frequency service life of up to 200,000 cycles based on precise spring design and high durability materials. This pogo pin connector maintains stable contact force and elasticity at extremely high compression and decompression frequencies. Long life design can reduce fatigue damage and effectively resist the impact of external vibrations and temperature fluctuations on contact performance. Johoty’s spring loaded electrical connectors have excellent durability and stability, which can significantly reduce maintenance costs and improve the long-term operational efficiency of equipment

Wide environment adaptability

Extreme temperature range: Conventional pogo pin connectors can operate normally within -40°C ~ +85°C. Johoty’s specially designed spring loaded electrical connectors can operate stably at temperatures up to 250℃. Of course, this requires special alloy springs, surface treatment processes, high-temperature resistance Peek or PI. In this way, they can effectively resist the expansion and contraction caused by temperature changes, maintain a constant contact pressure, and avoid poor contact.

Corrosion resistance and protection: This requires high-performance materials and advanced surface treatment. Johoty commonly uses gold, silver, precious metal coatings or composite electroplating, which can effectively resist the erosion of air, moisture, salt spray, etc. When designing spring loaded electrical connectors, Johoty strictly screens insulation materials to prevent damage to internal components from chemicals, oil, and other substances. Antioxidant treatment and moisture-proof design, suitable for humid, dusty or salt spray environments. The unique corrosion-resistant and protective design makes spring loaded electrical connectors suitable for aerospace, military, marine, and industrial automation.

Anti vibration performance: Johoty often uses high-strength alloy steel or gold-plated alloy to make spring loaded pins. It has excellent elasticity and can effectively absorb and buffer the impact of external vibrations. Through precise spring design and structural optimization, spring loaded electrical connectors can maintain a constant contact pressure in high vibration environments, avoiding poor contact or signal loss.

Modularity and flexibility

Multiple sizes and specifications: Johoty’s spring loaded electrical connectors support up to 598 pins. Length 1.39mm~100.00mm, barrel diameter 0.50mm~32.00mm, stroke 1.00mm~20.00mm, spring force 15gf~1,000gf。 The shape of the needle includes a semi-circular head, a pointed end, and a flat head, cup,ball, crown 3, crown 4, crown 6, crown 9, wait. We can customize different pin lengths, spring forces, needle pitch configurations, and more to meet diverse design needs.

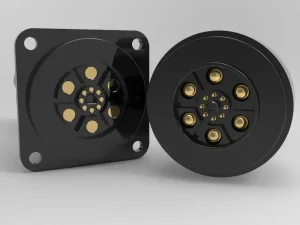

Diversified installation methods: We can provide 8 main categories of spring loaded electrical connectors. Including through holes, surface mounting SMT, solder cup, right angle, double ended (soldering-free), bending tail pin, threaded pogo pins. There are installations perpendicular or parallel to the PCB, as well as bending installations at various angles as needed with the PCB. Implement a higher density component layout to reduce the risk of plug-in damage.

Adaptive connectivity capability: Dynamic tolerance compensation: Spring loaded design allows for stable electrical contact within an axial displacement range of ± 0.5mm to ± 2.0mm, adapting to mechanical tolerance errors.

Support angle offset compensation: The tilt tolerance range can reach ±5°, ensuring stable electrical connection even in non-aligned states.

Precision spring: capable of absorbing mechanical vibrations and impacts, preventing contact interruption or signal loss. At the same time, this spring loaded pin can adapt to uneven contact surfaces, forming stable and secure electrical connections.

Key Performance Indicators for Spring Loaded Electrical Connectors

Electrical performance

Rated current: usually in the range of 0.5A to 50A, the specific value may vary depending on design, material, and application requirements. The rated current value of spring loaded electrical connectors is based on a comprehensive consideration of the load-bearing capacity of the internal pogo pins, the conductivity of the material, and the heat dissipation efficiency. This pogo pin connector can effectively compensate for small changes in the contact surface, thereby reducing electrical contact attenuation

Rated voltage: Typically ranging from 3.3V to 250V or even higher, Johoty designs spring loaded electrical connectors based on electrical insulation performance, contact resistance, temperature, vibration, humidity, and other factors. Provide reliable electrical isolation to prevent electrical short circuits, breakdowns, or arcs. Using insulation material PTFE PBT, Maintain extremely low leakage current and good electrical performance. Suitable for low voltage control or high voltage power supply scenarios.

Contact resistance: ≤30mΩ is a high-quality standard, which depends on the design of spring loaded electrical connectors, the material of spring loaded pins, proper finishing, and its usage conditions. Precision springs ensure that the contact surface remains stable during multiple insertions and high-frequency operations, reducing the increase in resistance. The pressure of the spring can compensate for contact surface deviations caused by thermal expansion, mechanical stress, or vibration. Low contact resistance can effectively reduce thermal effects and electrical noise, avoid fluctuations in contact resistance, and ensure low loss transfer.

Insulation resistance: usually >100MΩ, depending on the design of spring loaded electrical connectors, the insulation materials used and the application environment may vary. Insulation resistance is a key indicator for measuring the isolation capability of pogo pin connectors, which affects current leakage, resistance to electrical interference, and long-term stability. Commonly used PTFE, PBT, PA, PI, Has extremely low leakage current and excellent temperature and chemical resistance, maintaining extremely low current leakage. Always maintain high electrical isolation in high frequency, high voltage, or extreme environments.

Mechanical performance

Pin diameter and spacing: pogo pin diameter is generally ≥ 0.50mm, pitch≥1.00mm, Commonly 1.27mm, 2.54mm, supports high-density circuit design. The diameter of the pogo pin directly determines the stability and load capacity of the electrical contacts of spring loaded electrical connectors. The design of pogo pin spacing directly affects the layout, installation density, and resistance to vibration and impact of pogo pin connectors.

Spring stroke: The general range is ≥ 0.10mm, and the stroke size depends on the type and application requirements of pogo pins. It can automatically compensate for contact surface displacement or poor contact caused by temperature changes, vibration, mechanical stress, or insertion and extraction operations by adjusting pressure. Can enable spring loaded electrical connectors to maintain stable electrical contact on uneven or dynamically changing contact surfaces. Improve vibration and impact resistance to ensure uniform contact pressure. Suitable for temperatures ranging from -40°C to+125°C, able to maintain stable contact performance under temperature changes.

Plug and unplug lifespan: It can usually withstand a lifespan of 5,000 to 10,000 times, with some high lifespans reaching 50,000 times or more. Johoty’s special design can achieve 200,000 or even 300,000 cycles, meeting high-end connectivity requirements. The key factors affecting lifespan include spring design, high wear-resistant materials, precise design and high load adaptability, as well as resistance to vibration and impact. High lifespan spring loaded electrical connectors can significantly reduce costs, enhance reliability.

Spring force: Spring force refers to the force exerted by a spring in a compressed or stretched state, with a typical value of ≥0.15gf and no upper limit. Choose the appropriate pressure according to the contact requirements. It determines the contact pressure, wear resistance, and adaptability to temperature, vibration, and mechanical stress of spring loaded electrical connectors during the insertion and removal process. It ensures that the contact surface can always maintain appropriate pressure. It allows pogo pins to automatically adjust contact pressure to adapt to changes in contact surface caused by temperature fluctuations, mechanical stress, or long-term use. Improve the adaptability of pogo pin connectors to vibrations, impacts, and external forces. Appropriate spring force can help extend the lifespan of spring loaded electrical connectors.

Material properties

Pogo pins material: They are the key factors determining the mechanical, durability, and electrical performance of pogo pins. Including stainless steel, brass, copper alloy, Has good conductivity, high temperature resistance, and resistance to wear and corrosion. Gold plating layer, used for high-frequency, high-speed, and high demand electrical applications. Springs are commonly made of piano steel, stainless steel, spring steel, tungsten alloy, and are resistant to wear and compression. The material will affect the contact resistance, wear resistance, and corrosion resistance of pogo pins, as well as the reliability of spring loaded electrical connectors in high load and high-frequency applications.

Housing material: including PA, Nylon,PBT,PC,metal alloys,stainless steel,PTFE. Effectively prevent spring loaded electrical connectors from being damaged under high impact, vibration, and external forces. It has corrosion and chemical resistance, stable operation at extreme temperatures, excellent electrical insulation, and avoids EMI. Balancing durability and lightweight.

Spring materials: including piano steel, stainless steel, high carbon steel, titanium alloy, alloy copper, or nickel chromium alloy, providing excellent elasticity and fatigue resistance. Good Spring materials have significant advantages in elasticity, strength, durability, and environmental adaptability under high-frequency plugging, complex environments, and high load conditions.

Environmental adaptability

Working temperature: from extremely cold -55°C to high temperature +150°C, meeting industrial and special environmental requirements, Johoty can be designed to adapt up to 250°C. Spring loaded electrical connectors can adapt to thermal expansion at high temperatures, brittle changes at low temperatures, and thermal stress caused by sudden temperature changes.

Seismic performance: Utilizing preloaded contact force and adaptive contact compensation, from 10Hz to 2000 Hz, as well as impact acceleration up to 50G, maintaining low contact resistance and electrical stability. Vibration and impact testing in accordance with MIL-STD, ISO, and IEC standards.

Protection level: The female end of spring loaded electrical connectors can reach up to IP68. They maintain excellent electrical contact and mechanical integrity during prolonged immersion, high-pressure water jetting, and sandstorms. Compliant with ASTM B117, suitable for high-altitude low pressure and rapid temperature difference changes, engine compartment high temperature, high humidity, and sewage splashing environments. Prevent coolant, lubricating oil, and metal dust from damaging spring loaded electrical connectors. Resistant to seawater erosion and high salt spray environment, suitable for ship communication equipment and offshore energy systems.

High speed transfer: Can pass compatibility verification tests for high-speed data transfer via 10 Gbps Ethernet, USB 3.2, HDMI 2.1. Special spring design can resist spring loaded pin micro motion caused by mechanical vibration, reducing signal loss or jitter caused by vibration

Selection suggestions

Determine application requirements:

Clarify electrical performance: Based on current, contact resistance, voltage, insulation resistance, signal integrity requirements, signal characteristic selection, and appropriate voltage carrying capacity specifications.

Confirm mechanical requirements: Size and shape, needle material and coating, pogo pin size, spring stroke, spring force, pogo pin lifespan to ensure compatibility with equipment design requirements.

Environmental adaptability: Working temperature range, protection level, chemical resistance, high humidity and climate adaptability. Anti EMI, ESD protection, radio frequency interference (RFI) suppression, vibration and impact resistance, corrosion resistance. High voltage tolerance as well as high current carrying capacity.

Materials and Certification: Selection of high-performance metals and phosphor bronze, stainless steel, or high-temperature resistant engineering plastics. Compliant with RoHS, REACH, ASTM, UL, ISO, etc.

Specific requirements for the application: High-density design, blind mating, thermal compensation and temperature drift, EMC, Elastic travel and contact stability.

Cost: Matching the project budget, specifying the timeline for sample and bulk supply, long-term cooperation, technical support, and after-sales service.

Cost and Supply Chain:

Single item cost analysis: including material cost, processing cost, and coating cost, with clear price tiers for small and large batch purchases.

Total Cost of Ownership: The impact of the number of insertions and removals on long-term costs, comparing initial investment with long-term usage and maintenance costs, in order to optimize the overall project budget.

Cost balance of material selection: The impact of various materials such as gold plating, silver plating, or low-cost alloys on performance and price.

Fast delivery: Fast sample delivery and short lead time of 2 weeks, customizable product production cycle of 3-4 weeks.

Conclusion

Choosing the right spring loaded electrical connectors can significantly improve stability and efficiency of your project. With perfect connectivity solutions and excellent and professional technical support, Johoty can help engineers achieve higher design goals. Contact Johoty immediately to customize spring loaded electrical connectors, so you can ensure the smooth progress of your project. Don’t miss out, place your order now!