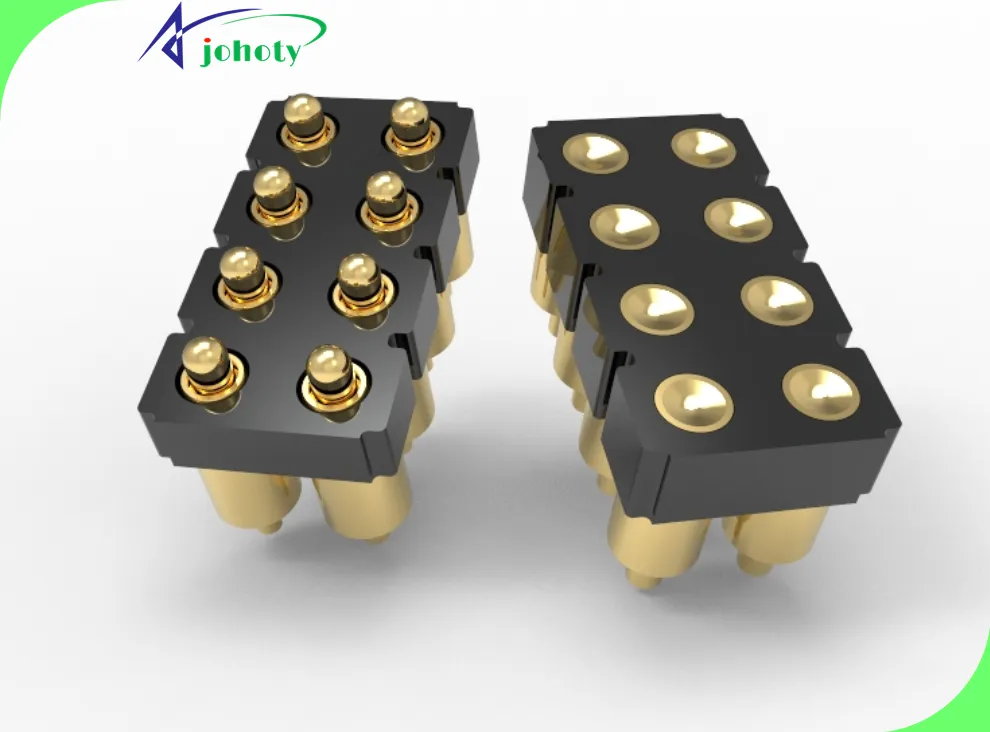

8 Pin Connector Description:

8 Pin Connector Datasheet:

| Items | Details |

|---|---|

| Electrical | Contact resistance: 15 mΩ ~ 200 mΩ, Custom. |

| Rated current: 1.0 A to 10 A, Custom. | |

| Rated voltage: 3.3 V to 230 V, Custom. | |

| Insulation impedance: ≥100 MΩ, Custom. | |

| EMI: Support. Custom. | |

| Transfer speed: Up to 5Gbps | |

| Working frequency: From MHz to GHz, Custom. | |

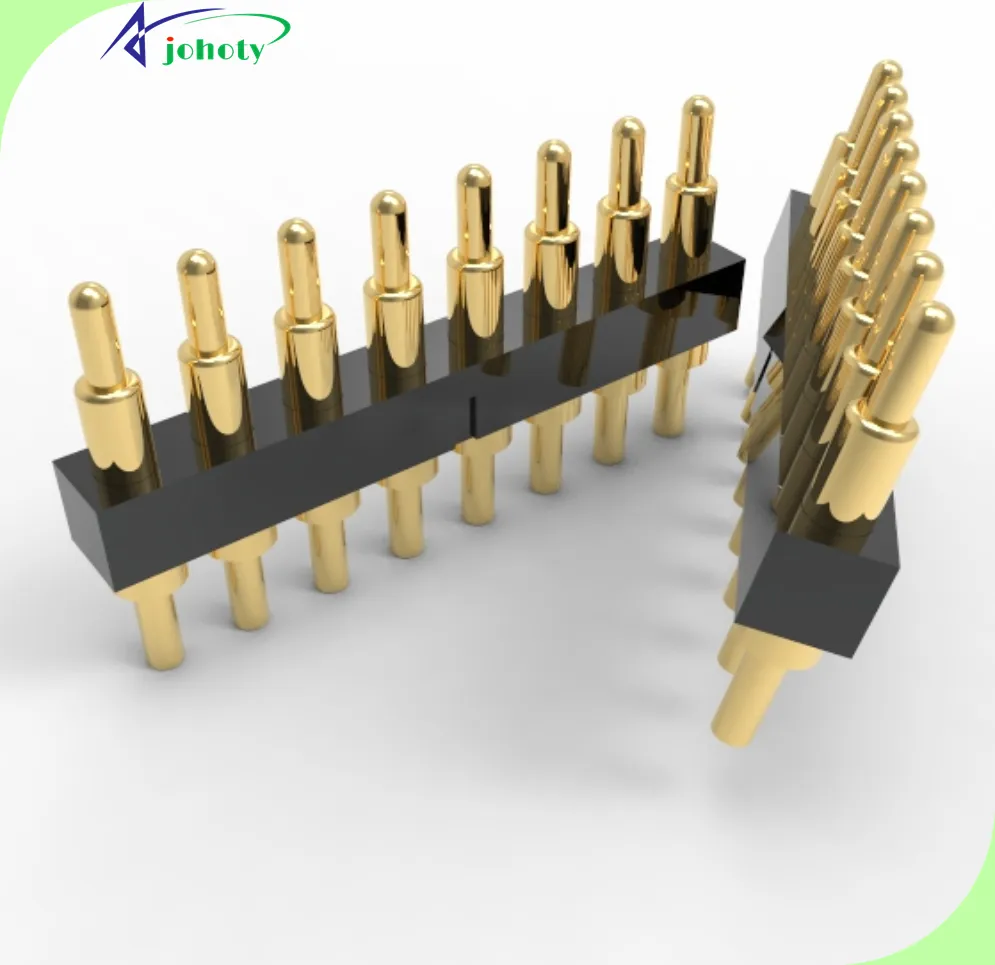

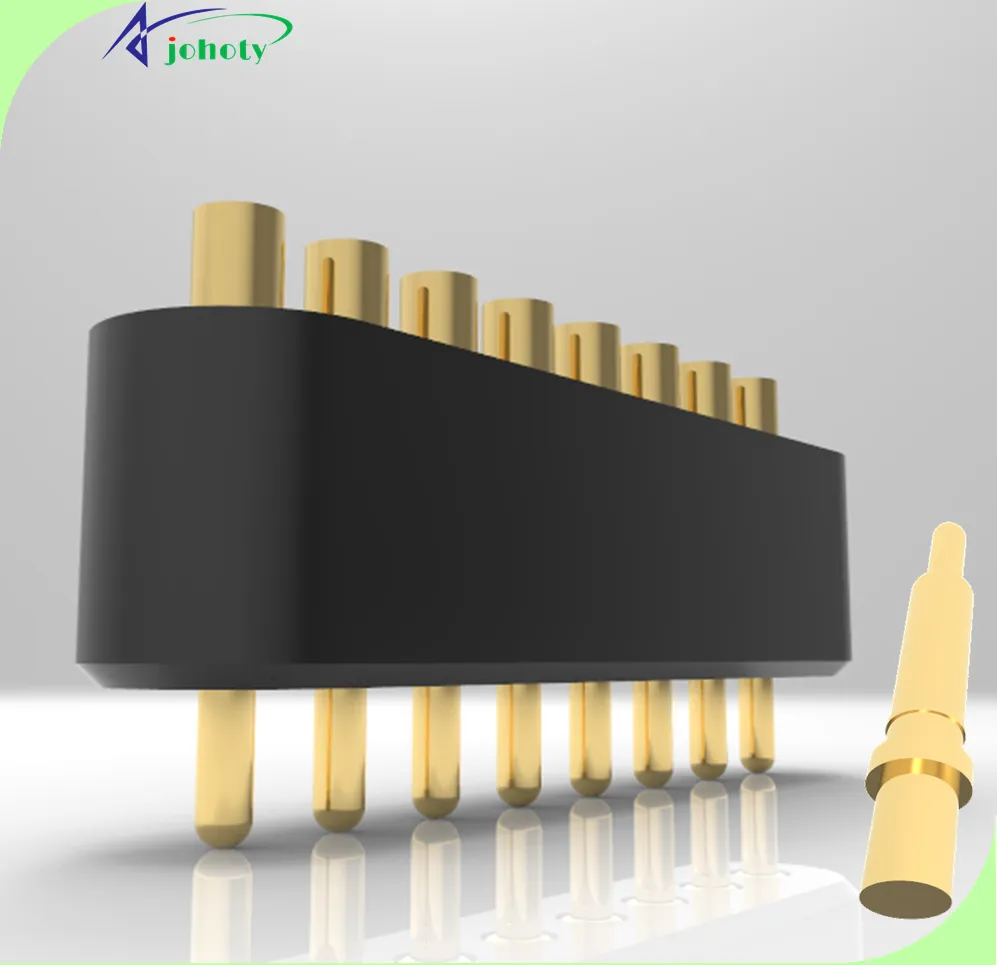

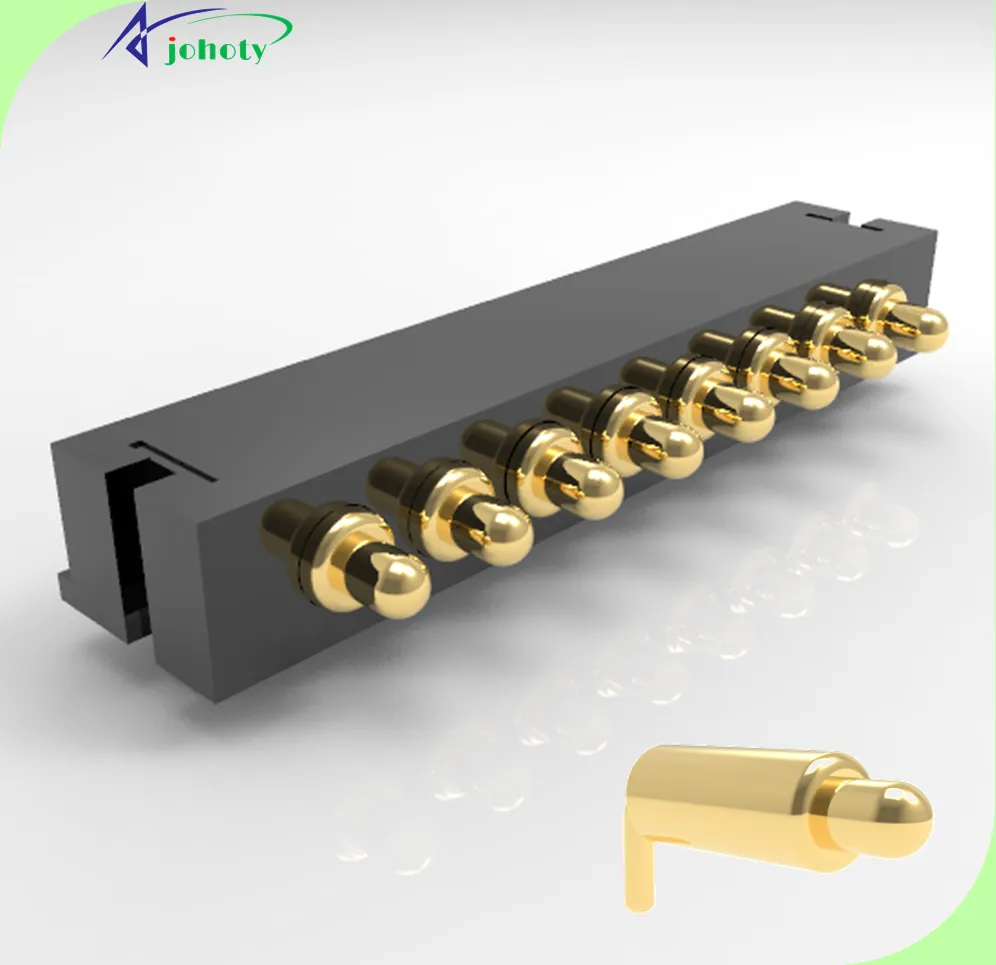

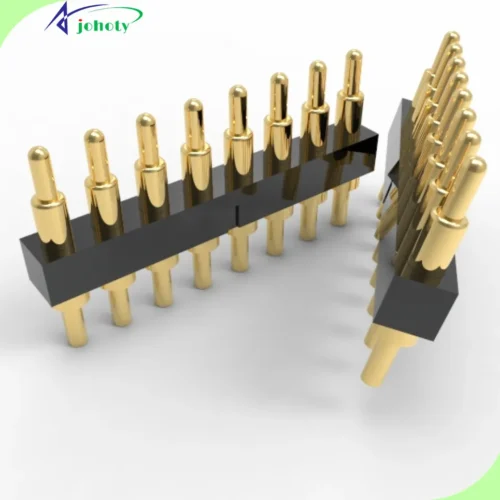

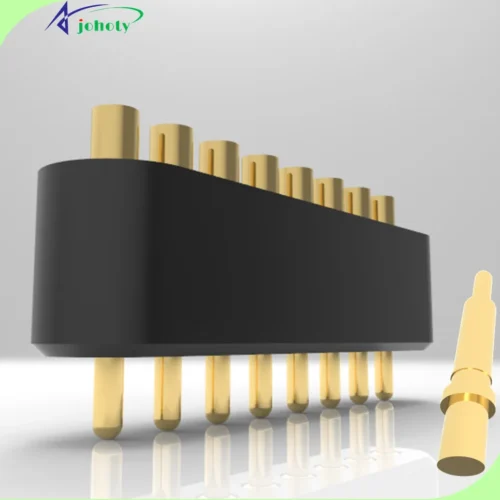

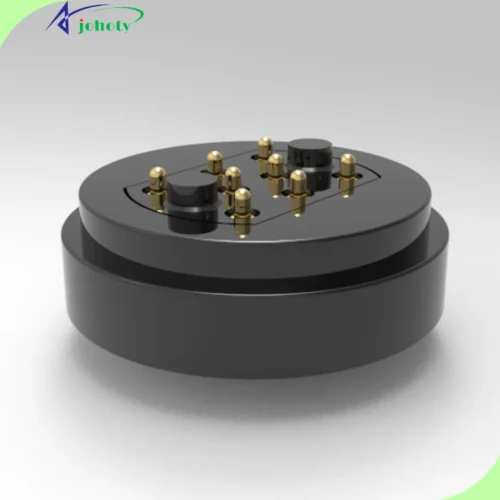

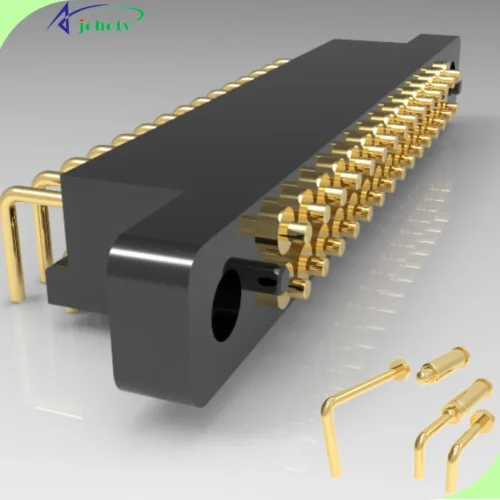

| Mechanical | Shapes: 8-pins, single/dual rows, Rectangle, Round, SMT, DIP, Solder-cup, Dual-end, Right-Angle, Bending type, Custom. |

| Spring force: 30gf, Custom. | |

| Pitch: ≥2.00mm, 2.54mm is popular, Custom. | |

| Stroke: ≥0.40mm, Custom. | |

| Length: ≥3.60mm, Custom. | |

| Barrer diameter: ≥1.00mm, Custom. | |

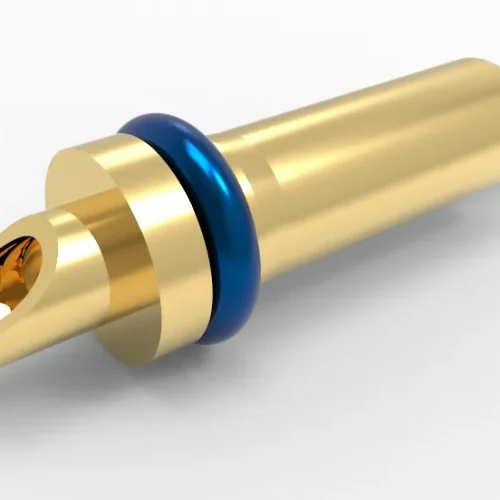

| Waterproof: IP65, IP66, IP67, IP68, Custom. | |

| Impact resistance: 10G to 50G, Custom. | |

| Vibration resistance: 10G to 50G, Custom. | |

| Life cycles: 10,000 ~ 200,000 times, Custom. | |

| Hardness: 20 HRC to 60 HRC, Custom. | |

| Working temperature: -40°C ~ +85°C (some: -55°C ~ +125°C). | |

| Storage temperature: -40°C ~ +100°C (some: -55°C ~ +150°C). | |

| Materials | Plunger/Barrer: Brass, copper alloys (beryllium copper, tellurium copper), stainless steel, etc. |

| Housing: Plastics (nylon, PA66, PTE, PPS, PBT), stainless steel, aluminum alloy, etc. | |

| Spring: Gold-plated, music steel, stainless steel, etc. | |

| Ball: Steel, zirconium, ceramic, Custom. | |

| Sealing: Silicone, rubber (fluoro rubber, EPDM), polyurethane, etc. | |

| Coating: >1.5u”, Gold, silver, nickel, Pd, Pt, Ru, Rh, passivation treatment, etc. | |

| Soldering: Tin, lead-free solder, silver solder, etc. | |

| Insulation material: PI, PTFE, PBT, Nylon, Polyurethane, silicone, rubber, etc. | |

| Eco-friendly: RoHS, REACH, L/F, H/F, etc. | |

| Flammability rating: UL94 V-0, etc. | |

| Installation | Surface mount: SMT, vertical, automated production line. |

| Through-hole: Stable, high current, mechanical stress resistance. | |

| Right Angle: Bent tail pin, surface mounting, limited space or a dynamic connection. | |

| Soldering: High current. | |

| Spring: Anti-vibration, anti-impact, high-vibration. | |

| Embedded: High waterproof and sealing requirements. | |

| Quick: Testing equipment. | |

| Locking: Screws, nut, additional mechanical fixation force. | |

| Slot: High requirements for connection stability. | |

| Package | Bulk, T&R(tape and reel), tray, tube, blister, plastic bag, Custom. |

Why Choose Johoty’s 8 Pin Connector?

8 Pin Connector has ±0.05mm accuracy. Johoty helps over 1,000 businesses get a jump on the competition and is trustworthy!

8 Pin Connector Benefits:

Stable and Reliable 8-Point Connection

Support Power, Data, Multiple Signals

Easy to Maintain and Replace

We can help you with modular design, reduce maintenance difficulty, decrease replacement frequency, and have a lifespan of over 10000 times. Shorten downtime, support plug and play, reduce operational difficulty, decrease maintenance frequency, improve efficiency, and ensure supply chain stability.

Improve Production Efficiency and Equipment Performance

Johoty helps you reduce installation and debugging time and achieve efficient electrical connections. Improve equipment performance stability, simplify production line layout, high durability and fatigue resistance, stable operation under harsh conditions, support high current and high power, and reduce downtime.

8 Pin Connector Applications:

Smart Wearable Devices

Medical Equipment

Automotive Electronic Devices

Consumer Electronic Devices

Industrial Control Equipment

The machines in the factory are powerful and require accurate signal and power transmission between them. The 8 pin connector plays a role in the brain nerves here. It can maintain stable connection in high temperature, vibration environments, and high humidity of the machine, allowing all devices to work synchronously. The robotic arms used to transport parts on the production line rely on such 8 pin connectors to coordinate their movements, which are fast and error-free.

New Energy Equipment

New energy sources, solar panels, and wind turbines require the transmission of electrical energy from equipment to energy storage devices. At this point, the 8 pin connector came in handy. It can work in strong wind, rainstorms, or high temperatures. This type of pogo pin connector is stable and durable, allowing new energy equipment to continuously generate electricity. The 8 pin power connector helps reduce our dependence on traditional energy and makes the earth greener.

Communication Equipment

Aerospace and Aviation Equipment

8 Pin Connector Advantages:

High Reliability and Durability

Excellent Conductivity

Strong Anti-corrosion and Environmental Resistance

Strong Compatibility

Flexible Customized Services

Easy Installation and Time-saving

FAQ

Highlight the safety design of the 8 pin connector. Like overload protection, dust, and waterproof capabilities, and any additional safety measures that most customers care about.

We can show you testing steps during production, the quality of materials used, and quality certifications or guarantees. like ISO certifications or other industry-relevant ones.

Give detailed specs, this involves assessing the capacity of 8 pin connector to manage maximum current and voltage safely. Crucial for assessing if it’s fit for a particular application.

If high-speed data transfer is necessary for certain applications, detail the maximum data transfer rate that the 8-pin connector can accommodate. Including whether it accommodates USB 3.0, 3.1, or other high-speed communication standards.

Give an overview of the best pricing of our 8 pin connector. Including discount policies for bulk purchases, MOQ, and expected delivery times and logistics options.