Discover How IP67 Connector is to Change Industrial Engineering by Offering Unmatched Durability, Reliability, Protection in Harsh Environment

Introduction: Why is IP67 connector so important?

In the field of industrial engineering, the reliability and durability of equipment have always been a challenge faced by engineers. In harsh environments, traditional connectors often become a hidden danger of equipment failure due to water erosion, high temperature, or high vibration. Johoty’s IP67 connector provides strong technical support for solving these problems based on magnetic attraction, shock resistance, and other features.

Why is IP67 connector so important? How does Johoty revolutionize industrial engineering and bring perfect solutions to engineers? Johoty will delve into IP67 connector unique advantages and show you how it can solve modern industrial engineering problems.

Core advantages of IP67 connector

IP67 connectors can enhance the durability and stability of devices, simplify installation and maintenance, and reduce failure rates and costs. It has brought revolutionary advancements to industrial engineering. For engineers, IP67 connector is undoubtedly a key technology that cannot be ignored in future industrial equipment.

Enhance the durability of equipment to cope with harsh working environments

For engineers, equipment often needs to operate stably in high temperatures, humidity, dust, or corrosive gases. Traditional connectors often face the risk of performance degradation or failure in these environments. The protective function of Johoty’s IP67 connector ensures your devices’ long-term stability. In outdoor construction sites and manufacturing workshops with extremely high humidity, IP67 connector can maintain excellent working conditions. By using O-rings or silicone, your equipment can avoid downtime caused by connector failures, reducing maintenance costs, frequency, and time.

Reduce equipment maintenance and downtime, lower costs

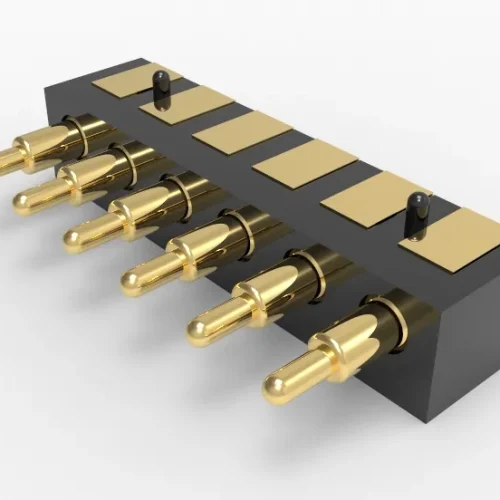

The biggest headache for engineers is the frequent intermittent failures of equipment, where damage to connector components leads to unstable operation and shutdown of the equipment. Due to the waterproof, corrosion-resistant, and dust-proof design of IP67 connector, it greatly reduces the failure rate of equipment in harsh environments. The high durability and stability of Pogo pin connector eliminate the need for frequent maintenance or replacement by engineers. After installing Johoty’s IP67 connector, it will definitely help you solve the intermittent instability of the device, improve reliability and service life. On-site engineers on the production line can find significant savings and OEE improvement in maintenance costs and downtime.

Simplify installation and connection to improve work efficiency

Johoty pays attention to protection performance when designing IP67 connector, and also considers ease of use in industrial applications. This pogo pin connector often adopts a quick connect design, making your installation process easier. For engineers, the ability to install, debug, and replace our pogo pins in a short amount of time is key to improving production efficiency. IP67 connector helps engineers efficiently complete tasks during tight working hours by reducing installation complexity and time.

Strong compatibility, multi scenario application

The IP67 connector has excellent compatibility and can be used for automation control, sensor connection, and interconnection of power equipment. This compatibility allows IP67 connector to be applied to different types of industrial equipment, avoiding compatibility issues caused by improper connectors. IP67 connector have become a standard configuration in robotics technology, intelligent manufacturing, and energy management.

Corrosion resistance and extended equipment lifespan

Customer feedback: Chemicals, liquids, or gases can cause corrosion and shorten the service life of ordinary connectors. Johoty’s IP67 connector uses excellent materials and sealing design, with extremely strong corrosion resistance. This anti-corrosion performance makes our pogo pin connector an ideal choice for petrochemical, power industry, and marine equipment. In this way, engineers can effectively protect equipment in highly corrosive environments and ensure long-term efficient operation.

Environmental adaptability ensures system stability

Modern industrial engineering systems typically require continuous operation at extremely cold or hot temperatures, high humidity, and high salinity. Under these conditions, traditional connectors may experience performance degradation, intermittent unstability, or even complete failure. The design of Johoty’s IP67 connector can operate stably between -40℃ and+85℃. The specially designed Johoty pogo pin connector can achieve stable operation at 250℃. It can greatly enhance the environmental adaptability of the system. With this wide range of temperatures and environmental adaptability, engineers can confidently apply Johoty’s IP67 connector to devices in various special environments.

Applications of IP67 Connector

Equipment connection in chemical plants

The environment of chemical plants is complex, filled with toxic gases, liquids, and large amounts of dust, which may affect the normal operation of equipment. Conventional connectors often fail to provide sufficient protection in such environments, resulting in poor connections and even device damage. The IP67 connector, with its powerful sealing design, effectively prevents chemical corrosion, dust, and moisture from entering. It can ensure equipment’s stable handling, reduce failures and maintenance. Reduce equipment failures caused by environmental pollution and improve the normal operation time of production lines.

Sensor connection in high humidity environment

In the food processing and pharmaceutical industries, equipment needs to operate in high humidity environments. Moisture can cause short circuits or poor contact in the internal circuit of the connector, seriously affecting the stability and lifespan of the equipment. Johoty’s IP67 connector can effectively prevent water vapor infiltration, and the device can operate stably for a long time. Our pogo pin connector enables devices to operate efficiently in humid environments without any malfunctions caused by moisture.

Electrical connection of outdoor equipment

Everyone knows that wind turbines, solar panels, and remote monitoring equipment all need to work in outdoor environments. Rainwater, dust, and extreme temperatures in outdoor environments can have a serious impact on equipment. Johoty’s carefully designed IP67 connector is waterproof and dustproof, effectively protecting the electrical connections of these devices. Regularly use silicone, O-ring sealed pogo pin connectors themselves or your device to avoid connector damage and equipment failure. Based on long-term feedback from customers, outdoor equipment is not affected by weather changes and can effectively extend its service life.

Protection of ships and offshore platforms

Ships and offshore oil platforms are constantly subjected to extremely harsh conditions such as salt spray, seawater immersion, and strong storms. Based on composite coating, Johoty’s IP67 connector is highly suitable for use in these environments due to its waterproof, salt spray resistant, and corrosion-resistant properties. This pogo pin connector can effectively prevent electrical failures caused by harsh environments in devices. Composite coating can effectively prevent the corrosion of pogo pins coating by acidic and alkaline liquids, and ensure IP67 connector lifespan. It can significantly reduce the failure rate of offshore equipment, improve production safety and stability.

Electrical Connections in the Automotive Industry

More and more automotive electronic components are being integrated into the electrical systems of cars. These components are often exposed to high temperatures, dust, chemicals, and moisture. Johoty’s IP67 connector can effectively protect these components, ensuring automotive electrical systems is perfect in complex environments. Based on IP67 waterproof or IP68 waterproof, Johoty’s pogo pin connector can help customers improve the reliability of their car’s electrical system. This can avoid malfunctions, instability, intermittent, or accidents caused by connection issues.

Connection of industrial automation equipment

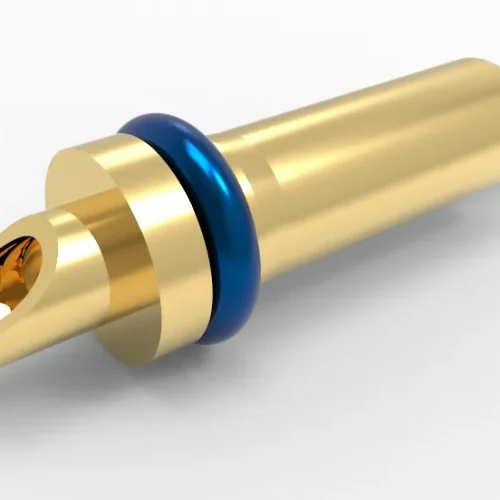

In the production workshop, industrial automation equipment is usually exposed to dust, liquids, and mechanical impacts during operation. Johoty designs IP67 connector with high-quality brass plated with gold, palladium, rhodium, ruthenium, and platinum for wear resistance, dust resistance, and impact resistance. It can effectively prevent these environments from affecting the normal operation of equipment and ensure the efficient operation of automation systems. The pogo pins with built-in springs can stably connect, improve the durability of automation equipment, and reduce equipment downtime.

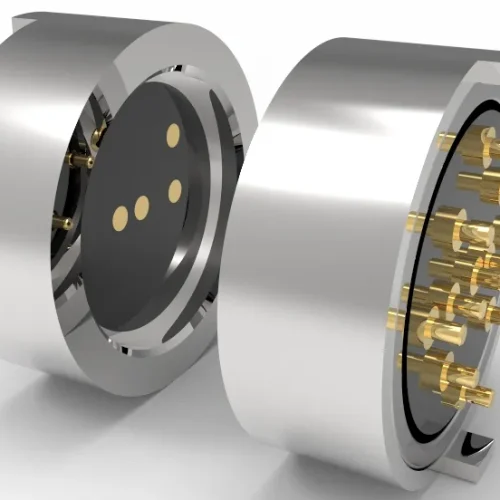

Electrical interface between robots and robotic arms

Industrial robots and robotic arms are often used in high-precision manufacturing processes, requiring extremely high work efficiency and stable operation for long periods of time in changing environments. We will also use 5-axis CNC or even 6-axis CNC to ensure high precision of IP67 connector. This pogo pin connector can efficiently prevent the intrusion of moisture and dust, ensuring stable electrical connections for robots in harsh environments and improving production efficiency. Precision spring design and composite coating extend lifespan of robots and robotic arms, ensuring high-precision operation during the manufacturing process.

Common problems and solutions for engineers:

Ensuring equipment’s long-term stability is a huge challenge in complex environments. And Johoty’s IP67 connector can be easily designed as a magnetic connector, fully composite with customers’ various shapes, performance, interface methods. It has strong waterproof, dustproof, corrosion-resistant, earthquake resistant and durable properties, providing an ideal solution to solve engineers’ problems. In high temperature, underwater, high humidity, acidic and alkaline liquids, and harsh industrial environments, Johoty IP67 connector can ensure equipment’s efficiency and safety. Based on Johoty’s perfect and flexible solution, it can assist in technological innovation of industrial engineering.

Common questions for engineers:

Equipment reliability in harsh

Industrial equipment operates in environments with high temperature, high humidity, seawater, vibration, or dust. How to ensure connectors can still function properly in these extreme environments is challenge engineers must face.

Long-term exposure of equipment to water and dust

Many industrial equipment need to operate outdoors or in humid, even in rainy or snowy weather, in contact with liquids, and cleaned in washing machine fluids. Conventional connectors are prone to short circuits or corrosion, leading to equipment failure.

Stability and durability of connectors

In industrial applications, the stability, corrosion resistance, intermittent failures, connectors durability directly determine equipment’ long-term reliability. How to reduce equipment failures, safely pass high currents, and lower maintenance costs has become an urgent concern for engineers.

Challenge of diverse interface requirements

Intelligence of industrial equipment often requires different types of devices to have multiple interfaces. This requires connectors to have extremely high flexibility and compatibility to meet different devices. Many engineers require a 2pin~40pin spring loaded connector to connect to USB, HDMI, Molex connector, Type-C, etc.

Perfect solutions for IP67 connector:

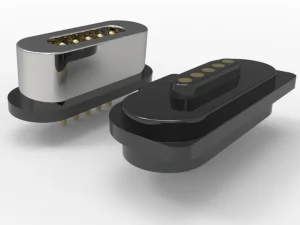

Waterproof and dustproof designs

Johoty’s IP67 connector can completely prevent dust from entering and can withstand short-time of underwater. It is often divided into female and male designs, achieving IP67 or IP68 waterproof. The equipment can maintain stability in humid, seawater, high humidity, outdoor with severe dust. Common designs include o-rings, silicone, and 2-3 flanges on barrel, which can effectively prevent malfunctions caused by external environments.

Durability and reliability

Johoty’s IP67 connector is typically produced of high-quality brass and pass 23 quality tests. It has excellent impact resistance, scratch resistance, corrosion resistance, and oxidation resistance. Under prolonged vibration, high temperature, lateral force, or extreme environments, this pogo pin connector can still maintain excellent conductivity and stable signal transfer. This is what engineers want, and after years of customer verification, Johoty’s IP67 connector can greatly improve the stability as well life cycles of your equipment.

High compatibility and flexibility

Our IP67 connector come in various specifications and support multiple interfaces, making them compatible with various devices. Circular interface, square, rectangular male and female ends, capable of designing up to 20 different shapes for plunger tip. This includes round, pointed, flat, claw head with 3,4,6,9 tips, cup head. And, tail pin of solder-cup, through-hole, flat bottom, double head, right angle, etc. Engineers only need to tell Johoty to obtain IP67 connector that meet different industrial equipment.

Reduce maintenance costs

Because IP67 connector has high protection and can also be designed as IP68 waterproof, it can significantly reduce equipment failure. Based on Johoty’s composite electroplating and high-quality brass,IP67 connector has high stability, wear resistance, and environmental resistance. Device always requires such connection performance, which can greatly reduce maintenance costs. For industrial enterprises, Johoty’s IP67 connector is the guarantee of higher operational efficiency and lower operating costs.

How can IP67 connector drive innovation in industrial engineering?

Engineers often face electrical connection reliability issues in extreme environments, such as dust, high humidity, vibration, chemical corrosion, etc. IP67 connector has excellent protection levels and are revolutionizing industrial engineering. It can help engineers solve these big challenges and drive technological upgrades across multiple industries.

Reliable protective performance enhances equipment durability

The IP67 connector can prevent dust from completely entering and works normally underwater for 30 minutes. Such protective performance is crucial for manufacturing, automotive, energy, and automation.

- Industrial automation: The environment in factory workshops is usually filled with dust and moisture, and traditional connectors are prone to moisture and short circuits. Johoty’s IP67 connector ensures long-term stability of PLCs, sensors, and actuators.

- Cars and Rail Transit: Our IP67 connector can ensure reliable connection of electrical systems in outdoor, mud, rain, snow, etc., preventing malfunctions caused by water intrusion.

Quick installation and maintenance to improve production efficiency

Equipment shutdown means significant economic losses for industrial applications, and the quick connect design of IP67 connector greatly reduces installation time

- The wind and solar power industry: On-site maintenance is usually carried out under harsh conditions. The tool free connection design of Johoty’s IP67 connector reduces manual operation time and improves operation and maintenance efficiency.

- Robots and automated production lines: The modular design of IP67 connector allows for quick replacement of sensors and drivers, reducing production downtime.

Anti-impact and anti-vibration, ensuring high dynamic environmental stability

Equipment in industrial engineering often needs to operate in high vibration or impact. Johoty’s IP67 connector features an enhanced mechanical locking design that can resist external impact and prevent accidental detachment

- Heavy machinery and engineering vehicles: Connectors in construction and mining equipment need to withstand severe vibrations for a long time. IP67 waterproof ensures its long-term durability, and based on N52 magnetic design and thread locking, this pogo pin connector can fully provide high stability.

- Aerospace and military applications: In aircraft, drones, and tactical equipment, impact resistance is crucial, and IP67 connector can provide safe and stable connections.

Compatible with high-power and high-speed data transmission, adapting to the needs of intelligent industry

Industry 4.0 and IoT devices often require faster data communication and more stable power supply. Joy’s IP67 connector supports:

- High speed Ethernet connection: supports high-speed communication protocols, Gigabit Ethernet, DP signal transfer, USB 3.0. Fiber optic cables are suitable for intelligent manufacturing and automated detection systems.

- High power connection: suitable for devices with high current transfer, such as electric motors, charging and discharging devices, BMS, HVDC power supply, etc., to improve industrial power supply efficiency.

Multi material protection, suitable for extreme working conditions

The IP67 connector is made of corrosion-resistant alloy, stainless steel, and industrial grade plastic, Johoty can also provide very complex composite electroplating. In addition to non-medical nickel plating as the bottom layer, we can provide non-magnetic coatings, nickel free medical coatings, palladium plating, rhodium plating, ruthenium plating, platinum plating, etc. Our flexible customized pogo pin connector can adapt to acidic and alkaline solutions, extreme temperatures, seawater, chemical corrosion, and more.

- Chemical and pharmaceutical industries: resistant to chemical corrosion, suitable for acidic and alkaline solvent environments. After being washed for a long time under the EMS system, the pogo pins inside will not rust or short-circuit, and the latter will be scrapped.

- Ocean engineering: anti salt spray, anti oxidation, waterproof design, Johoty’s IP67 connector has very strong protection and stability functions in offshore wind power and ship automation. After 3 years of tracking testing by our Dutch and Italian customers, it seems that our pogo pin connector performance can pass the rigorous verification of our customers.

Conclusion:

With the increasing complexity of industrial environments, equipment’s durability and reliability have become more critical than ever before. IP67 connector have become an ideal choice for engineers to solve common problems in harsh environments based on its excellent waterproof, magnetic, and shock-absorbing. Whether it’s improving device stability, reducing maintenance costs, or extending lifespan, Johoty’s IP67 connector provides strong support for industrial engineering.

If you want to improve performance and reliability in engineering projects, avoid frequent failures and shutdowns caused by environmental factors, choosing IP67 connector is definitely your wisest investment. Contact Johoty immediately to choose IP67 connector that suits your needs and embark on a more efficient and reliable industrial engineering design!