PCB Pogo Pins: 10mΩ Contact Resistance, 50A Current, High-Performance, Perfect for Precision Engineering and Aerospace Solutions. Get Yours Now!

PCB Pogo Pins: High performance connectivity solution to meet precision engineering.

PCB pogo pins are commonly used as important connectors in modern engineering and manufacturing industries. Excellent performance is favored by engineers in the fields of aerospace, electronic equipment, and automation systems. In high demand precision engineering applications, these PCB pogo pins often demonstrate excellent high quality. Over the years, from European and American engineers contacting Johoty for solutions, they have proven to be very effective.

Here, Johoty will show you the key features and applications of PCB pogo pins. Help various enterprises and engineers better understand the value of this key component in high-performance environments.

High quality contact resistance: PCB Pogo Pins ensure stable connection.

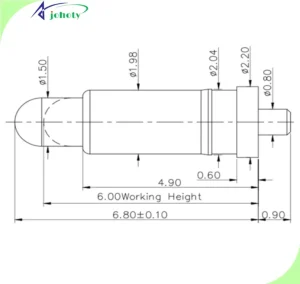

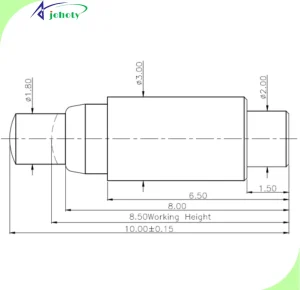

The contact resistance of pogo pins is usually required to be between 20mΩ and 100mΩ. Some customers also request an extremely low contact impedance of only 10mΩ. They need to maintain extremely low resistance values during the connection process. And after 10,000 connection cycles, it maintains only an 8% impedance boost. This is crucial for electrical and electronic products and is highly suitable for high-speed data transmission. High contact resistance may lead to power loss, signal attenuation, and even equipment failure. Therefore, low contact resistance ensures stable transmission of signals and power, greatly improving the reliability of electrical equipment.

The data shows that reducing contact resistance can effectively improve your system efficiency. And reduce heat generation, lowering the failure rate. This is very critical for long-term operation and high stability. For example, in aerospace and military equipment, any small fluctuation in resistance can lead to system failure. Even causing catastrophic consequences. Therefore, you can try Johoty’s PCB pogo pins with a contact resistance of 10mΩ. They can improve equipment performance and overall system security.

Powerful current carrying capacity: PCB pogo pins adapt to complex systems.

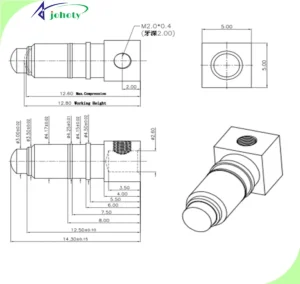

The current carrying capacity of PCB pogo pins usually reaches 10A~20A. Johoty can achieve up to 50A and is commonly used in pogo pin connectors with 2-pin and above. They can meet high-power current for the vast majority of customers. For devices that operate stably in high-power environments, this parameter is extremely critical. In automation equipment, power transmission systems, and high-performance computers, customers often come to us to order pogo pins ranging from 100A to 600A. Stable current transmission can ensure the continuous operation of equipment and avoid system crashes caused by current fluctuations.

In the aerospace field, Pogo pins need to carry high currents to ensure stable current transmission. Johoty’s 100A pogo pins enable engineers to ensure long-term stable operation of these critical devices. 100A~200A is very common in high-tech systems that require efficient power management.

Strong spring force: Stable connection performance of PCB pogo pins.

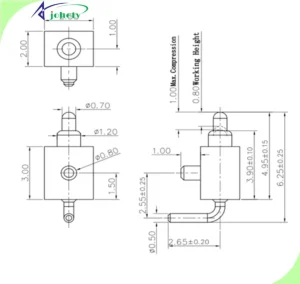

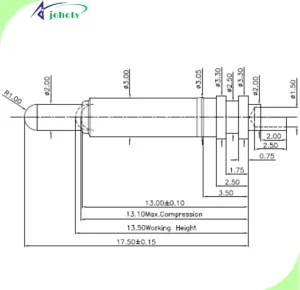

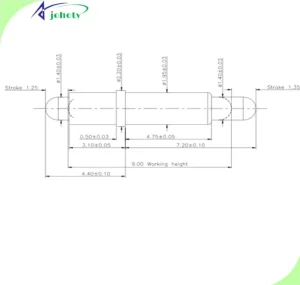

A high-quality PCB pogo pin must have sufficient spring force, typically requiring a spring force of 50gf~200gf. For pogo pin connector with a large number of pins, only 5gf is what customers crave. This is the key to ensuring a stable connection between client’s circuit board and Johoty’s spring loaded pin. The magnitude of spring force directly affects the mating performance and durability under frequent operation.

Strong spring force can effectively prevent poor contact of connectors caused by vibration or external interference. This can effectively improve the equipment reliability. In automated production lines, frequent operations require connectors to have stable spring force. It can maintain precise contact and stable current transmission during high-speed operation.

Long lifespan: PCB pogo pins are a durable choice.

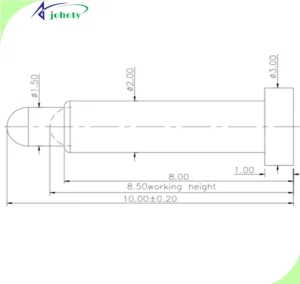

The lifespan of PCB pogo pins is usually over 10,000 cycles, and Johoty can design up to 200,000 cycles. It has become a must-have in many industries that require high durability and long-term stable operation. Compared to other types of connectors, the lifespan of pogo pins far exceeds that of typical electronic components. As a result, Johoty is able to obtain inquiries and orders from European and American aerospace, military, and high-precision equipment customers.

Continuous stability and durability are important and crucial for precision equipment used at high frequencies. The extended lifespan of PCB pogo pins reduces replacement frequency and customer maintenance costs. The production line and equipment can operate continuously and stably. In an unmanned environment, this reduces manual maintenance.

High precision gold plating process: The key to improving signal transmission quality for PCB pogo pins.

Many pogo pins use high-precision 0.125μm gold plating technology. This is a common coating thickness, and high-end applications also require gold plating up to 5.0μm. This can improve the corrosion resistance of pogo pins and significantly enhance their electrical performance. In high-frequency or high-power transmission, the gold surface can reduce current loss. Improving signals’ transmission efficiency can also prevent pogo pin corrosion and enhance its wear resistance. In video signals and high-speed high-frequency signals that require precise signal transmission, 5.0μm gold plating is very important.

In the aerospace field, signal stability is crucial for the control system of equipment. Any small signal interference can lead to system failure. The golden surface can effectively resist oxidation and wear, ensuring the long-term stability of customers’ equipment. PCB pogo pins can effectively prevent signal loss or errors.

Applications of PCB Pogo Pins

High power current transmission for automation equipment and power management systems:

In systems with efficient power and stable transmission, Pogo pins can carry up to 50A of current. Industrial automation and power management often require them. Its low contact resistance of 10mΩ ensures high efficiency in current transmission and avoids excessive heat generation. Equipment operating at high loads requires high conductivity with low impedance. Using high current connectors can reduce system failure rates and energy consumption, resulting in overall high operational efficiency.

High precision mechanical connections between aerospace and military systems:

PCB pogo pins have a lifespan of up to 200,000 cycles, making them ideal for aerospace and military applications. Because each connection point can work continuously and stably under extreme conditions. Using a finishing with up to 5μm gold plating, the connector has a stable signal at high frequencies. Simultaneously resistant to corrosion and wear, meeting high reliability standards.

High frequency signal transmission of precision electronic equipment:

Products that require precise signal transmission, PCB pogo pins can provide stable low contact resistance and gold plated surfaces. Avoid signal loss or attenuation. Low contact resistance (10m Ω) and gold-plated surfaces are essential in communication equipment, precision instruments, and high-end consumer electronics. This can ensure long-term stable operation for equipment overall performance improvement.

The high vibration environment of robots and automated assembly lines:

Robot systems and automated assembly lines often need to withstand high vibrations. The spring force of PCB pogo pins ≥5gf can ensure connection stability. The connector will not loosen or disconnect due to its vibration or surrounding external interference. The spring force can keep the system running continuously without frequent maintenance during high-frequency plugging and unplugging.

Long term reliability of high-end medical equipment:

PCB pogo pins have a lifespan of up to 200,000 cycles, making them an ideal choice for medical devices. Monitoring instruments and diagnostic equipment often require long-term stable operation. With their durability, medical equipment remains highly reliable even under harsh conditions. Reduced equipment malfunctions and maintenance needs.

Efficient data synchronization of precision testing and measuring equipment:

Precision testing equipment often requires efficient signal transmission capability and contact performance. PCB pogo pins have high-precision gold plating and low contact resistance. Data synchronization is very reliable. In high-end testing equipment, this efficient connection can transfer stable and accurate data. At the same time, you can get equipment’s high performance and accuracy.

Conclusions:

PCB pogo pins have excellent contact resistance, current carrying capacity, spring force, long lifespan, and gold plating process. Has become a leader in high-performance connectors. They are commonly used in aerospace, military, automation, robotics, and other fields. It also demonstrated superior performance in high demand environments. With the continuous advancement of technology, the value of Johoty’s PCB pogo pins in the field of precision engineering will only become increasingly prominent.

Many customers seek high-performance connectivity solutions or high-quality pogo pin connector. Johoty will provide ideal PCB pogo pins. We are committed to providing you with precise and efficient pogo pin connector. Meet the needs of top global manufacturers. If you would like to learn more about PCB pogo pins, please contact Johoty immediately. You will get professional consultation of technician and product.