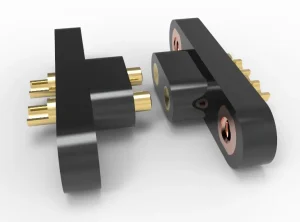

Board to Board Connector Based on High-Speed Pogo Pins for Maximum Signal Integrity and Durability. Johoty’s Optimized Designs for Engineers.

Introductions: Board to Board Connector

The requirements for high-speed data transfer, device miniaturization, and extreme environmental reliability are constantly increasing today. Traditional board to board connector design is facing unprecedented challenges. High frequency signal integrity, mechanical durability, and stable connections in a compact layout are often difficult to fully meet the stringent requirements of engineers with standard connection solutions.

If you urgently need a connection solution that balances high-speed transfer, ultra-high durability, and ultimate miniaturization. The innovative board to board connector driven by high-speed pogo pins may be the answer.

This blog will provide an in-depth analysis from an engineer’s perspective: why traditional spring pins and conventional connectors are unable to meet the demand applications of new generation? How can high speed pogo pins overcome bandwidth bottlenecks and mechanical fatigue? How to achieve the best balance between signal integrity, mechanical lifespan, and miniaturization design for a board to board connector? Meanwhile, Johoty also showcases successful applications in high-frequency communication, medical equipment, automotive electronics based on high-speed pogo pins.

Not only is there an analysis of cutting-edge technology here, but there are also practical engineering inspirations that can be directly implemented. If you are facing the demand for high-speed, high-frequency, and durable small connections, you may want to continue reading. And, explore this new option that could completely rewrite the connection solution.

Read: Through hole high-speed board to board connector

Why choose Johoty’s high-speed Pogo Pins? Best answers for high-speed board to board connector

In today’s world where high speed, high density, and high reliability have become hard standards, traditional connectors can no longer meet the stringent requirements of the new generation of electronic systems. Johoty’s high-speed pogo pins, born for challenges, it is becoming preferred choice for engineers in board to board connector.

High speed signal integrity: insertion loss and return loss performance far exceed traditional connectors

In high-speed designs of 5Gbps or even 10Gbps or above, any small signal distortion can lead to system crashes. Johoty’s high-speed pogo pins reduce insertion loss to below -1.0dB (@ 6GHz) and control return loss within -15dB. It is by optimizing the spring structure and contact material, which is superior to conventional connectors. Actual test data shows at the same distance, signal eye diagram aperture of Johoty pogo pins is increased by 25%. Effectively ensuring complete data transfer.

Reliable contact force: stable connection under high-frequency vibration and thermal cycling environment

In environments with high-frequency vibration (>20Grms) and harsh thermal cycling (-40°C~125°C), traditional connectors often experience signal loss due to micro motion wear and poor contact. Johoty’s pogo pins are designed with patented spring mechanics and paired with anti fatigue alloy materials. In continuous 5,000 hour high-frequency vibration aging test, the change rate of contact resistance is less than 5%. Stability exceeds industry average, truly achieving reliable connectivity in extreme environments.

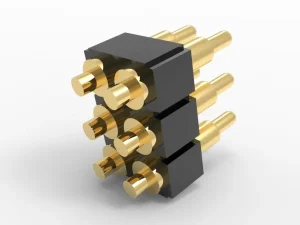

Miniature design flexibility: support for minimum pitch size and free customization of layout

As devices become increasingly ultra-thin and highly integrated, connectors must evolve towards smaller pitch sizes. Johoty high-speed pogo pins support a minimum pitch of 1.0 mm. We can customize linear, matrix, and irregular layouts according to customer needs. Perfectly adapted to various compact board to board connector designs. No need to sacrifice performance for space, helping products achieve simultaneous breakthroughs in size and performance.

Excellent durability and long lifespan: >10,000 plug cycles standard

Johoty’s pogo pins have passed rigorous durability testing for applications with multiple insertions. Tested according to IEC60512 standard, after more than 10,000 cycles of insertion. The change in contact resistance is less than 10%, and there is no significant decrease in mechanical properties. The common lifespan of traditional board to board connectors is 5,000 to 10,000 cycles. Johoty’s pogo pin connector significantly reduces maintenance and replacement costs throughout its lifecycle, making it a trusted choice for engineers.

Read: Surface mounting high-speed board to board connector

Design points of Board to Board connector based on High Speed Pogo Pins

High speed signal transfer has become a standard configuration for 5G, medical electronics, and intelligent automotive equipment today. How to design a board to board connector that truly meets stringent application requirements has become a core concern for engineers. The design based on high-speed pogo pins requires finding the optimal balance between performance, reliability, and lifespan.

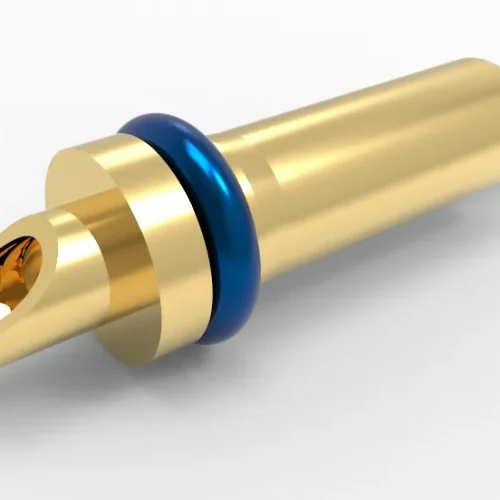

Optimization of spring pin structure: why is multi-stage spring more suitable for high speed?

Although traditional coil springs are simple, they are prone to bouncing, micro motion, and unstable contact impedance in high frequency. Multi-stage spring adopted by Johoty significantly reduces dynamic jitter and signal reflection by precisely controlling compression path and force. For high-speed board to board connector, this can improve contact consistency and significantly extend device lifespan.

Material selection for contact interface: gold plating thickness and Ni Barrier layer design

High frequency signals are extremely sensitive to interface changes. Johoty used a gold plating layer with a thickness of over 3 μm in the design, effectively reducing the interface contact resistance. At the same time, Johoty accurately optimizie the thickness and distribution of the Ni Barrier layer. Magnetic interference at high frequencies was effectively suppressed (Eddy Currents). This directly determines the high-speed stability and anti-aging performance of board to board connector in 5G module and millimeter wave radar.

Layout and signal path optimization: reduce discontinuity and improve consistency

In Board to Board connection, every millimeter of path variation may cause signal integrity issues. Johoty uses shortest path design and coaxial symmetrical layout. Minimize impedance discontinuity to the greatest extent possible and maintain phase and amplitude consistency of high-speed signals. For applications that require transfer rates above 6GHz, such optimization is crucial.

Multi point contact and redundant design: enhance fault tolerance and ensure long-term stability

Johoty’s high-speed connector introduces a multi-point contact mechanism in its design. Even if there is wear or contamination at a single point of contact, reliable conductivity can be maintained at other contact points. At the same time, redundant path design has been added to cope with extreme environments, further enhancing reliability. This is a decisive advantage for scenarios that require high stability, such as medical equipment and automotive electronics.

Customization ability: precise tuning according to different applications

The requirements for board to board connector vary greatly in different applications. Johoty can customize parameters such as spring force, stroke, size, coating combination, frequency bandwidth, etc. according to customers. The maximum speed applicable to 5G communication modules and the ultimate requirements for long lifespan and corrosion resistance of medical equipment. More suitable for the stringent standards of automotive electronic anti-vibration performance, Johoty can provide optimal solutions through deep customization.

Read: Double ended high-speed board to board connector

Application of Board to Board Connector Project Based on High Speed Pogo Pins

Precise connection ignites high-speed dreams

Under the wave of high-speed interconnection and device miniaturization, board to board connector has reached a new height. High-speed pogo pins, has excellent signal integrity and extreme space adaptation capability. It has become the preferred connectivity solution for many cutting-edge projects.

5G communication module high-speed interconnection project

Project background: A network communication equipment manufacturer in Texas, USA, is developing the next generation of 5G small base station modules. Customers face strict requirements for stable transmission of high-frequency signals above 6GHz. At the same time, customers also need to achieve multi-point connections in limited PCB space.

Main challenge: High frequency signals are easily affected by the elastic deformation of the pins, leading to a decrease in signal integrity. The standard board to board connector structure is too bulky to meet the requirements of module miniaturization.

Solution: Adopting a multi-stage Pogo Pin spring structure to optimize contact stability and reduce transmission path jumps. The gold plating thickness on the contact interface has been increased to 50 μ in, and combined with Ni Barrier shielding, it significantly reduces crosstalk between pins.

Performance improvement data: S-parameter test results: Insertion Loss reduced by 15% in the 6.5GHz frequency band. Eye Diagram analysis: The window opening rate has been increased to 92%, and the signal quality has been significantly optimized. The volume is effectively reduced by 30% compared to traditional board to board connectors.

Challenge of miniaturization and connection of medical imaging equipment

Project background: In a new portable ultrasound imaging equipment project, a US client requested to achieve extreme miniaturization. Moreover, the customer guarantees the durability of high-frequency plugging and unplugging, and the connector needs to withstand multiple plugging and unplugging operations per day, with a lifespan requirement of over 200,000 times.

Main challenge: The internal space of the device is extremely limited, with only a 3mm height tolerance. Frequent plugging can easily bring traditional connectors’ performance degradation.

Solution: Johoty uses high elasticity high speed pogo pins customized for medical miniaturization devices to ensure stable compression stroke. Introducing a multi-point contact design to reduce the risk of single point failures and enhance redundancy.

Verification data: After 200,000 cycles of insertion and extraction testing, the contact resistance change was less than 10%. The transmission performance of the 3GHz signal remains above 95% of the initial value. Successfully controlled the total height of the connector within 2.8mm.

Read: Solder cup high-speed board to board connector

Frequently Asked Questions and Answers for Engineers on Board to Board Connector

The increasing demand for high-speed and high-density connectivity poses unprecedented challenges to the design of board to board connectors. With the maturity of high-speed pogo pins technology, more and more engineers are paying attention to:

Will Pogo pins be more prone to signal integrity (SI) issues in high-speed signal transfer than traditional pins?

In fact, high-speed pogo pins that have been structurally optimized can effectively reduce SI risks in high-speed board to board connector applications

Multi segment spring design: Compared to traditional single coil springs, it adopts a segmented transition structure, effectively reducing signal path mutations.

Contact interface optimization: The contact points are coated with high hardness gold and nickel barriers to reduce contact resistance, signal reflection, and crosstalk.

High frequency simulation verification: Actual tests have shown that using a customized pogo pin board to board connector reduces Insertion Loss by nearly 18% and increases Eye Diagram to over 90% in the 6GHz frequency band.

Properly designed high-speed pogo pins will not become a bottleneck for SI, but can instead unleash greater potential in high-speed board to board connector applications.

How to maintain consistency of each Pogo Pin in mass production?

The consistency of mass production determines the long-term performance stability of board to board connectors. We adopt the following strategy:

CNC precision machining: The tolerance of each Pogo Pin part is controlled within ± 0.01mm.

Automated assembly testing: Built in pressure testing and displacement monitoring to screen out any abnormal parts.

Batch reliability testing: Conduct high-frequency performance sampling before each batch is shipped to ensure stable signal performance above 6GHz.

Johoty’s key reminder: full chain control of raw materials, processing accuracy, and assembly process is extremely important. Otherwise, even if the design is well-designed, it is difficult to ensure the final consistency of the board to board connector.

Is the Pogo Pin connector stable in the temperature range of -40°C to +125°C?

Verified high-speed pogo pins are fully capable of handling applications in extreme environments. The key elements include:

Material selection criteria: Select special alloys with extremely low temperature brittleness and matching thermal expansion coefficient.

Surface treatment: The coating process can effectively resist the risks of high temperature oxidation and low temperature brittle fracture.

Environmental testing verification: After passing the temperature cycling test from -40°C to +125°C, the change in contact resistance is less than 10%.

Therefore, in automotive electronics and aerospace with a wide temperature range, it fully possesses mass production stability. Because Johoty always uses board to board connectors designed with high reliability pogo pins,

What are the distances between boards, transfer rates, and application scenarios suitable for Pogo Pin?

Board distance: The standard travel design supports board distances ranging from 0.5mm to 4.0mm. The special customized version can be extended to 6mm or more to accommodate larger module tolerances.

Transfer rate: Depending on the specific stroke and contact surface design, it can support up to 10Gbps or more. It usually performs best in the frequency range below 6GHz and is suitable for most high-speed interconnection scenarios.

Typical applications: High speed interconnection of 5G communication modules, micro connection of medical imaging equipment. Automotive radar and camera module, industrial automation high-speed acquisition system. Aerospace harsh environment interconnection.

Read: Right angle high-speed board to board connector

Why choose Johoty’s Board to Board Connector based on High Speed Pogo Pins?

Rich industry experience:

Johoty has successfully delivered over 3,000 high-speed connectivity solutions in the fields of communication, healthcare, automotive, and new energy. Our high-speed connectors are applied to board to board connectors, helping multiple industries improve system performance and reliability. Johoty can provide precise solutions for high-speed signal transmission or miniaturization design. Meet customers’ demanding requirements for high frequency and low latency.

High speed customization research and development capability:

As a leading manufacturer of high-speed connectors, Johoty has a dedicated team of engineers who design board to board connectors. We can quickly respond to customer needs, from design to sampling, ensuring that every project can be delivered in the shortest possible time. Johoty can flexibly respond to both small batch customization of board to board connectors and large-scale production. We can ensure that board to board connectors always meet your needs based on the highest standards.

Reliability verification standards:

Our high-speed pogo pin connector complies with ISO, RoHS, REACH, and other standards. Ensure that every board to board connector undergoes rigorous quality inspection and reliability verification. The complete testing report provided by Johoty ensures that every pogo pin connector has excellent performance and long-lasting durability. They can meet the requirements of various harsh application environments.

Widely used in the industry:

They can be used in communication equipment, medical imaging equipment, automotive electronics, and new energy fields. Johoty’s board to board connectors provide solid technical support to customers worldwide. Our pogo pin connector is capable of carrying high-speed signals and has multiple advantages such as earthquake resistance and oxidation resistance. They can perfectly adapt to high-frequency requirements in complex environments.

Technical support and ASS:

Johoty is committed to providing comprehensive technical support and after-sales service. From technical consultation during the design phase to process optimization during mass production, Johoty always works closely with clients to ensure the smooth progress of projects. For any problems encountered during use, Johoty always provides quick response ASS. Ensure that customers can use our board to board connector without worry.

Choosing Johoty means choosing a professional, reliable, and efficient connectivity solution. We provide you with high-performance and highly reliable board to board connectors. We will also help you stay ahead in technology research and market competition.

Read: Bending type high-speed board to board connector

Conclusions: Board to Board Connector for high-speed connections, starting from Johoty

High speed pogo pins are undoubtedly one of the core technologies for achieving excellent performance in designing high-speed board to board connectors. Johoty has a deep understanding of engineers’ needs for high frequency, low latency, and long lifespan. Our high-speed connectivity solution can meet these demanding technical requirements. From high-frequency signal transmission to high-density interconnection, our board to board connectors undergo strict quality control and performance verification. They will all work continuously and stably in harsh application environments.

As a leading provider of board to board connector in the industry, Johoty focuses on the research and customization of high-speed pogo pin connectors. Our high-speed pogo pins design not only meets the high-performance demands of modern communication, healthcare, automotive, and new energy industries. Complete the rapid iteration from design to sampling in a very short response time, helping customers quickly achieve product implementation.

Many clients’ projects require miniaturization design and complex high-speed signal transmission requirements. Johoty’s board to board connector can provide you with flexible, reliable, and efficient technical support. Johoty’s CFT team works closely with you to ensure that every design proposal is tailored to practical applications.

Today, choosing Johoty means you have chosen a high-quality, high-performance, and customized board to board connector. We not only provide high-density connectivity solutions, but also promise to provide you with comprehensive technical support and industry-leading after-sales service. Make Johoty your reliable partner for innovative and efficient connectivity. Contact Johoty immediately to activate your high-speed board to board connector.