How Do Gas Springs Work? This blog explores the nuances of gas spring mechanics. Reveal how they effortlessly achieve smooth movement and comfortable adjustments for surgical tables. Explore how this technology brings convenience and comfort to the medical industry. Satisfy engineers’ curiosity for technical details and practical applications.

How Do Gas Springs Work? Utilizing compressed gas, Gas Springs function as devices to exert force for regulating motion. In most cases, you’ll see a cylinder and piston setup, filled with nitrogen, filled with compressed gas, such as nitrogen. When the gas spring contracts or extends, pressure is generated by the gas enclosed within the cylinder Thereby generating a force opposite to the direction of piston movement.

This technology finds prominent application in medical equipment, such as surgical table adjustments. By installing gas spring systems on surgical tables, medical staff can easily adjust the height and angle of the table. This can meet various surgical requirements while Making sure patients have a pleasant and comfortable experience.

Gas Springs not only offer reliable motion control but also boast features of smoothness, quietness, and reliability. This makes them an indispensable component of medical equipment.

Introduction, How Do Gas Springs Work? Easily Adjust Surgery Tables to Comfy

- In the field of medical equipment, ensuring surgical tables’ comfort and convenience has always been a significant challenge for engineers. During the surgical procedures, medical staff need to adjust the surgical table’s height and angle effortlessly. It is to ensure both patients and doctors can operate in optimal positions. The application of Gas Springs technology is aimed at addressing this challenge.

- We will explore how Gas Springs technology works and how it makes the adjustment of surgical tables easy and comfortable. Here, delving into the working principles and applications of gas springs. We will reveal how this technology plays a crucial role in the design of medical equipment. Provide a better working and treatment experience for medical staff and patients.

Problem Statement:

- Have you ever wondered how surgical tables achieve comfortable adjustment functionality? How do Gas Springs make the operation of surgical tables so effortless? This piece will reveal the solutions to these issues and delve into the engineering principles. And practical applications of gas spring technology.

Basic Principles of Gas Springs, How Do Gas Springs Work? Easily Adjust Surgery Tables to Comfy

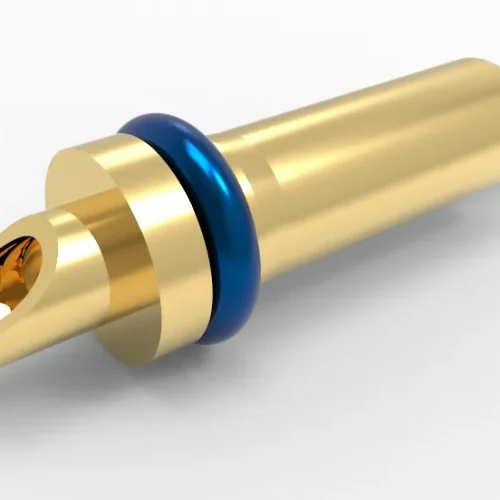

The Construction of Gas Springs

It is relatively simple yet highly effective. It consists of two main components:

- Cylinder: This is a sealed tube, typically made of metal, used to contain compressed gas.

- Piston: This is a movable component that fits snugly against the inner wall of the cylinder. It can move within the cylinder, separating the gas inside.

The Function of Compressed Gas

- The basic principle of gas springs is to utilize the force generated by compressed gas for motion control. With compressed gas occupying the cylinder, pressure disperses evenly throughout.

- As the gas spring contracts or extends, the piston movement changes the volume of the gas, thereby altering its pressure. The gas pressure, coupled with the piston’s movement direction, dictates the outcome. The gas spring will generate a force opposite the piston movement’s direction.

The Working Principle of Gas Springs

- When a gas spring is pushed by an external force, the piston moves, causing an increase in gas pressure. This increased pressure generates a force opposite to the direction of piston movement, thereby counteracting the external force. When the external force ceases, the gas spring remains in its new position until acted upon by external force again.

Application Cases

- Gas springs have wide-ranging applications in the engineering field, including the automotive industry, furniture manufacturing, industrial machinery, and more. In medical equipment, gas springs are commonly used on surgical tables to provide comfortable adjustment and smooth motion control.

- By utilizing gas spring technology, medical staff can easily adjust the height and angle of surgical tables. Ultimately, this fosters an improved working environment and enriches the surgical journey for patients.

Comfortable Adjustment of Surgical Tables, How Do Gas Springs Work? Easily Adjust Surgery Tables to Comfy

Surgical tables are a crucial component of medical equipment. Because they directly impact the efficiency of medical personnel and the care experience of patients. Ensure surgical tables meet the needs of different surgical scenarios and the comfort of medical staff and patients. They need to have the following special requirements:

Special Requirements

- Height Adjustment Capability: Surgical tables need to be adjustable to different heights to accommodate the needs of different doctors and surgical procedures. This ensures that doctors can maintain good posture during surgery, reducing their fatigue.

- Angle Adjustment Functionality: Surgical tables also need to be able to adjust angles, including tilt and translation functions. It can ensure that patients are in the optimal position and posture during surgery. This is notably significant for certain kinds of surgical treatments. Where the surgical site needs to be tilted or the patient needs to be at a specific angle.

- Stability and Safety: Surgical tables must have stability and safety to prevent accidental movement or tilting during surgery. This is crucial for protecting the safety of patients and medical staff.

Comfortable Adjustment Functionality of Gas Springs

The application makes the comfortable adjustment of surgical tables easier and more reliable. Here is an analysis of how gas springs achieve comfortable adjustment:

Smooth Motion Control:

- Gas spring technology enables smooth motion control of surgical tables, making the adjustment process smoother and more precise. Medical staff can easily adjust the height and angle of the surgical table without causing sudden movement or vibration.

Precise Adjustment Functionality: - Gas spring systems can provide precise adjustment functionality to meet the personalized needs of doctors and patients. Whether it’s minor height adjustments or large-angle changes, gas springs can achieve precise control. Ensure comfort and efficiency during surgery.

Safety and Reliability:

- Gas spring systems have high safety and reliability, providing stable support for surgical tables and maintaining the desired position. This means that medical staff and patients can use the surgical table with confidence. Without worrying about accidental movement or tilting.

- Through the application of gas spring technology, the comfortable adjustment of surgical tables becomes simpler and more reliable. Medical staff can easily adjust the position and angle of the surgical table. Affording patients a treatment experience that emphasizes both comfort and safety.

The Application of Gas Springs in Medical Equipment Engineering Design

Engineering design of medical equipment needs to consider patient comfort, convenience for medical staff, equipment reliability, and safety. The application of gas spring technology in medical equipment offers the following advantages:

Comfortable Adjustment Functionality

- Gas spring technology enables comfortable adjustment of medical equipment, especially on devices like surgical tables. With gas spring systems, healthcare professionals can effortlessly modify the height, angle, and placement of equipment.

- It is to accommodate different surgical requirements and personalized patient needs. This enhances the comfort and efficiency of surgical procedures.

Smooth Motion Control

- Gas spring systems feature smooth motion control characteristics, ensuring smooth and precise adjustment of medical equipment.

- This is particularly crucial for devices like surgical tables that require precise adjustments. It reduces the impact of sudden movement or vibration during surgeries.

Simplified Design and Operation

- Gas spring systems can simplify the design of medical equipment and enhance operational convenience. Compared to traditional mechanical adjustment devices, gas spring systems are typically simpler, lightweight, and require less maintenance.

- This allows medical staff to operate equipment more easily, saving time and effort.

Safety and Reliability

- Gas spring systems offer good safety and reliability, providing stable support for medical equipment and maintaining the desired position.

- This is crucial for safety and stability during surgeries, preventing accidental movement or tilting of equipment. Moreover, this safeguards the high security of both healthcare providers and patients.

Advantages and Limitations

Despite the many advantages of gas spring technology in medical equipment engineering design, there are also some limitations:

- Load Limitations: Gas spring systems have limited load capacity and may not meet the requirements of certain heavy-duty medical equipment.

- Temperature Sensitivity: The performance of gas spring systems may be affected by temperature, especially under extreme temperatures. This could result in diminished performance or complete system failure.

Despite these limitations, gas spring technology remains an important component of medical equipment engineering design. They contribute to fostering a superior working environment and treatment encounter for both medical staff and patients.

Technical Details and Engineering Considerations, How Do Gas Springs Work?

As a widely applied technology in medical equipment, the technical details and engineering considerations of gas springs are paramount. Below, we will delve into the technical details of gas springs and discuss in detail the factors to consider in engineering design.

Technical Details of Gas Springs

1. Pressure and Load Capacity:

- The design of gas springs must consider the required pressure and load capacity. This ensures they can stably support medical equipment and achieve the necessary adjustment functions.

2. Size and Shape:

- The size and shape of gas springs need to align with the design of medical equipment. It is to ensure proper installation and effective operation.

3. Material Selection:

- Optimal material selection is key to ensuring the efficiency and resilience of gas springs. Typically, stainless steel and aluminum alloys are common materials for gas springs, offering good corrosion resistance and durability.

Factors to Consider in Engineering Design

Load Requirements: In engineering design, it is necessary for an accurate assessment of the load requirements of medical equipment. This will determine the required specifications and quantity of gas springs.

1. Safety:

- Engineering design must consider the safety of gas spring systems to prevent accidental movement or tilting. Thus, prioritizing the security and welfare of both medical staff and patients.

2. Reliability:

- Gas spring systems must have high reliability, being able to stably support medical equipment and maintain the desired position. Even under prolonged use or high-load conditions.

3. Environmental Factors:

- Engineering design needs to consider the performance of gas spring systems under different environments, including temperature, humidity, and corrosion.

4. Maintenance:

- Engineering design also needs to account for the maintenance requirements of gas spring systems. This is to ensure long-term stable operation and performance.

Delving into the technical details and engineering considerations of gas springs. Engineers can better understand their application in medical equipment engineering design. And provide more comprehensive and effective guidance for the design and development process.

Conclusion, How Do Gas Springs Work? Easily Adjust Surgery Tables to Comfy

Through the discussion in this article, we have delved into the working principles of gas spring technology. And its applications in medical equipment, particularly its role in the comfortable adjustment of surgical tables.

In the engineering design of medical equipment, gas spring technology holds significant value. By utilizing gas spring systems, medical staff can easily adjust the height, angle, and position of surgical tables. This can meet the personalized needs of the range of surgeries and patient profiles. This not only enhances the efficiency and comfort of medical staff but also improves the treatment experience for patients. Alleviating discomfort during surgical procedures.

The advantages of gas spring technology

They lie in its simple, reliable, and precise adjustment functionalities, along with its smooth motion control characteristics. However, engineering design also needs to consider some limitations of gas spring systems, such as load restrictions and temperature sensitivity.

Nonetheless, gas springs remain an indispensable part of engineering design for medical equipment. Provide a reliable solution for the comfortable adjustment of devices like surgical tables.

When you need to order high-precision gas springs for medical equipment or other fields, contact us now! Choose us as your dedicated collaborator, providing end-to-end solutions from design inception to agile production and swift shipping!