In the fast-paced world of electronics, a smooth and reliable connection is a basic need for everyone. So, what does help us here: Pogo Pins

An electrical connection is built to another surface using a pogo pin, often called a spring-loaded pin. They are commonly used in electronic devices like tablets, laptops, and health industries.

Pogo pins are a versatile and reliable type of electrical connector. The reliability and durability of these connectors make them ideal for various applications.

Let’s get started with the function, structure, and applications of pogo pins.

Read: A Detailed Overview of Pogo Pin Types in Electronics

Basic Structure and Material of Pogo Pins

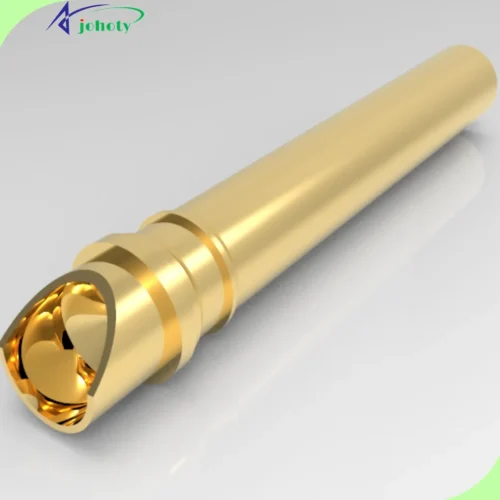

Pogo pins comprise three main components: Spring, Barrel, and Plunger. These components, which are responsible for connectivity, are designed using conductive and non-conductive materials.

Let us take a look at their materials and functions.

| Component | Function | Materials |

| Plunger |

|

|

| Barrel |

|

|

| Spring |

|

|

Read: 7 Ways To Use Pogo Pins: Jumpstart Your Next Projects

How Do Pogo Pins Work?

When you press a pogo pin against a mating surface, the spring compresses, and the plunger moves forward. As a result, the plunger establishes an electrical connection by contacting the mating surface.

The plunger retracts when the Pogo Pins are released, causing the spring to return to its original position.

To establish a reliable electrical connection between the pogo pin and the surface it connects with, the strength of the spring can be adjusted. In fact, the spring helps absorb shock and vibration, which can damage other electrical connectors.

Read: A Comprehensive Guide To Pogo Pin Chargers

Here are the key principles:

- Pogo pins are made of a conductive material that can carry electrical signals or power.

- The spring action in a pogo pin lets it adjust to different surfaces to make a solid connection, even if the two conductors are not perfectly aligned.

- Pogo pins do not build permanent connections. They are designed for temporary connections, such as charging, testing, or prototyping.

Read: Exploring The Applications Of Pogo Pins In Today’s Tech World

Advantages and Disadvantages

| Advantages | Disadvantages |

|

|

What Are Pogo Pins Used For?

In many applications, Pogo pins can be used, such as

- Laptops and other portable devices

- Medical equipment,

- Test equipment,

- Industrial automation

- Automotive electronics

- Data centers

- Telecommunications

- Consumer electronics.

Read: Exploring The Uses Of Pogo Pins In Various Industries

Conclusion

Pogo pins are a versatile and reliable type of electrical connector. Because of their durability and versatility, they are used in various applications.

Pogo pins significantly provide smooth communication between electronic devices, from PCB testing to battery charging.

If you are looking for a reliable and durable electrical connector for your application, Pogo Pins are a good option.

FAQ

How Long Do Pogo Pins Last?

Pogo Pins can last up to 10,000 mating cycles. Pogo pin parts consist of high-quality material, making them more durable and ideal for use in various industries.

However, the life span of a pogo pin depends on many factors, including its material used, its composition, and how it is utilized.

How Do Pogo Pins Work On Tablets?

Pogo pins work on tablets by making contact with the Pogo pin connectors of the device. These connectors are typically located on the bottom of the tablet and comprise a series of small metal pads.

The electrical connection between the pogo pins and the connectors enables the transmission of power, data, or other signals.

How Do Pogo Pin Headers Work?

A pogo pin header consists of a housing and an actuator. The primary purpose of these components is to establish a reliable electrical connection between a PCB and an external device.

The housing securely holds the pins in position while the actuator, often called the plunger, exerts pressure on them, causing them to contact the PCB.