Pogo pins are a great way to ensure your projects have reliable and consistent connections. You can efficiently make secure contacts with minimal effort with these versatile pieces of hardware.

This guide will give you the essential information on using pins and choosing the perfect one for many electronic connection needs.

Read: Exploring The Applications Of Pogo Pins In Today’s Tech World

Explore 7 Different Ways To Use Pogo Pins

You’ll inevitably wonder about the mounting options available if you consider pogo pins for your project. We’ll explore all these alternatives and provide some general guidance.

1- Mounting Pins with Solder Paste

The simplest method is to position the connector on a solder pad and utilize solder paste to secure it.

This method is straightforward but typically not recommended due to its lack of stability. There’s a risk that pins may break off or shift due to vibrations or mating pressure.

2- Using Pogo Pins with Plug-In Tails

This practice requires threading the component’s tail through a hole in the PCB – a standard procedure for most larger components.

The tail offers additional support to the pin, thus enhancing its stability.

3- Utilizing Housings with Legs

This procedure involves using housing with legs to mount the entire connector on the board securely.

Meanwhile, the pins are mounted on a gold pad using pressure or solder paste. This method offers enough stability for most applications.

4- Combining Plug-In Tails and Housings

Another method combines 2 and 3. It uses both housing and pogo pins with plug-in tails.

We typically recommend this mounting method whenever possible due to its superior stability.

5- With a Cable

They can be securely attached to the PCB using a cable. This method involves a small solder cup at the pin’s rear.

A wire is soldered to this cup, providing a flexible connection for more movement or adjustment after the pin is mounted. This approach is typically employed when a firm and direct connection isn’t feasible or preferred.

6- Through Spring Tails

An alternate innovative method involves attaching a flat spring piece to the end of the pogo pin on a PCB. This method offers an alternative mounting option, particularly useful for right-angle pins.

The springtail provides additional flexibility and durability. It makes it suitable for applications that require a higher degree of movement or that experience frequent wear and tear.

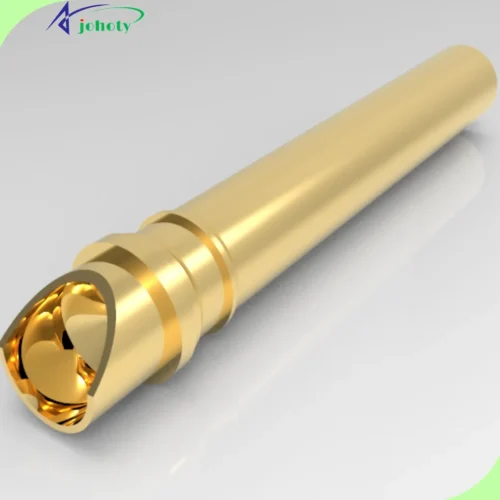

7- Using Double-Ended Pins for Mounting

A highly efficient method involves the use of double-ended pins. These pins can be press-fitted directly into the device housing or mounted on a plastic housing.

This method provides a sturdy and reliable connection. The double-ended design also allows for easier pins replacement if they become damaged or worn out.

Read: Exploring The Uses Of Pogo Pins In Various Industries

Precautions for Utilizing SMT with Pogo Pins

Consider Heat Resistance: Pogo Pins, like most components, can only resist heat up to a certain point. Standard housing and spring materials might not withstand the heat or multiple sessions of reflow soldering.

Select suitable pins and materials to prevent malfunction if you plan for multiple sessions.

Read: A Comprehensive Guide To Pogo Pin Chargers

Tips for Dip-Type Pogo Pin Connectors PCB Footprint Design

- PCB Hole Size: The PCB hole should generally have a radius equal to “Pogo Pin Tail + 0.3mm”.

- Soldering Gold Pad Size: The radius of the soldering gold pad should be “flange + 0.4mm”.

- Tail Length: The tail of the pogo pin should be designed with a length that is at least equal to the “Thickness of the PCB + 0.4mm”.

Note that these measurements may vary at smaller pitches and depend on your EMS’s operating tolerances.

Principles for Pogo Pin Connectors FPC Footprint Design

- Pin Tail Specifications: For Flex PCBs, the guidelines parallel those of regular PCBs. The tail length of the pin should be “FPC Thickness + 0.1mm”.

Guidelines for SMT Mounted Pogo Pin Connectors PCB Design

- Soldering Pad Dimensions: The size of the soldering pads should be “Pogo Pin Radius + 0.5mm”.

Read: A Detailed Overview of Pogo Pin Types in Electronics

Choosing The Right Pogo Pin.

Pogo pins are an excellent choice for creating testing jigs, particularly when you need to conduct the same quality assurance test on multiple circuit boards. You must position them, apply some pressure, and repeat the process.

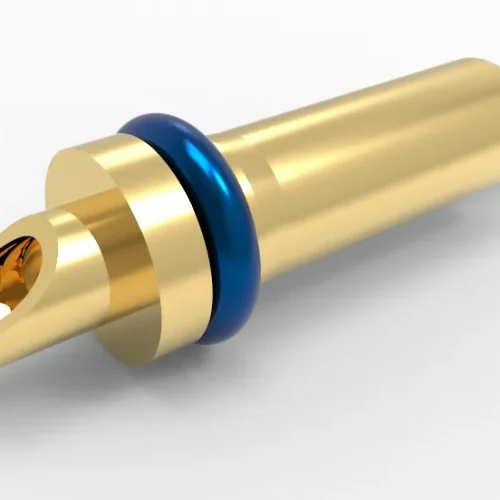

The circuit board you’re testing will likely influence which type of magnetic pogo pin connector you choose. For instance, the needle head pogo pin could be a great match if you’re testing small signal pads.

On the other hand, the cupped head pogo pin connector can snugly fit over small solder joints, like the top side of a row of header pins. The somewhat formidable spearhead pogo pin could be your best bet for dealing with empty through-hole pads.

Finally, the regal crown head pogo pin is better if you require more stability or increased contact with the test surface.

Read: Pogo Pins: Function, Structure, & Applications In Electronics

Conclusion

After completing each step for properly using your pogo pins and installation tools, you can confidently know you have the know-how to get the most out of these pins. Pins provide various applications.

You can put their many benefits to great use by understanding how to use them correctly. Furthermore, these make it easy to adapt to different situations and contexts with their small size, portability, and ease of connection.

FAQs:

What is the role of pogo pins in a tablet?

It tablets facilitate easy and efficient charging and data transfer between the tablet and other devices.

How can pins be secured?

They can be secured using various mounting methods, such as solder cups, springtails, or double-ended pins.

What role do pins play in testing?

They establish a temporary, reliable connection between the device under test and the PCB testing equipment, like a charger.

Is it possible to solder Pogo pins?

Yes, often attach a cable to a small solder cup at the back of the Pogo pin socket.

Can pogo pins be used as contacts in commercial products?

They are widely used as contacts in commercial products due to their secure, efficient, and flexible connections.

How do you ensure a good Pogo pin connection in Eagle?

Implementing a good pogo pin connection in Eagle involves designing suitable PCB layouts.

How do I connect to small pins in a test fixture?

Small pogo pins in a test fixture can be connected via a cable, springtail, or a double-ended pin.

What is the function?

In establishing electrical connections, pins enhance durability and resilience to mechanical shock and vibration. It is commonly used between two printed circuit boards.

Can you explain how These Pins operate?

The operation of Pins is based on their structure. It includes springs and magnets, offering a secure connection to various electronic devices due to their high durability and versatility.