What is IP67 Waterproof?

IP67 Waterproof Connector! Explore Limits, Fear No Challenge! 30m Underwater 1m! Most Reliable Connect for Outdoor, Industrial,Daily life.

IP67 waterproof is an international standard. It measures the dust and water resistance of devices. IP67 is ideal for outdoor activities, and dusty environments. Or where there may be contact with water. IP stands for “Ingress Protection”. It consists of two numbers:

The first number (range from 0 to 6)

Indicates the level of protection of the device against solid objects (e.g. dust). The bigger of number, the higher of dustproofing. 6″ in IP67 means that the device is completely dustproof.

The second number (range 0 to 8, or 9K)

Indicates the level of protection of the device against liquids. The higher the number, like dustproofing, the higher of waterproofing. 7″ in IP67 means you can completely place your devices for 1 meter deep in water for 30 minutes with no damage.

What are the design issues that most customers would like to address with IP67 waterproof?

By addressing these issues, customers want to ensure that their products. That can remain competitively superior in terms of performance, durability, user experience, and cost-effectiveness.

Raw material Selection and Cost Control

Select raw materials that can withstand water and dirt erosion while balancing cost and performance.

– Solution: We always conduct new raw material studies and cost-benefit analyses. The target is to select the best raw materials that are both economical and efficient.

Sealing technology

Ensure that all interfaces, buttons, and switches of your equipment are resistant to water and dirt intrusion.

Solution: Use advanced sealing technologies. such as rubber gaskets, sealants, etc. As well as ensuring the tightness of the design.

Durability and Reliability

Waterproof equipment needs to maintain functionality and performance. When exposing them to various harsh environments for a long time.

Solution: Conduct rigorous durability testing to ensure product reliability under extreme conditions.

User experience

Waterproof and dustproof without sacrificing the ease of use and functionality of your devices.

Solution: Design with user interaction in mind to ensure that your devices are still easy to use. Even with protection measures in place.

Thermal management

Waterproof design may affect the heat dissipation of your devices.

Solution: Design an effective heat dissipation system, such as using heat dissipation materials, heat sinks, or ventilation.

Weight and volume

Adding waterproof and dustproof features may increase the weight and volume of your device.

Solution: We always optimize the design to minimize the impact on weight and volume.

Testing and certification

Ensure that our IP67 connectors comply with IP67 and other relevant standards.

Solution: Undertake a rigorous testing process and be certified by a certification body.

Repair and maintenance

Ensure that the repair process will not damage the waterproof and dustproof characteristics.

Solution: We always design a structure of maintenance-friendly and provide professional maintenance guidance.

How Does the IP67 waterproof connector benefit R&D engineers in their design work?

IP67-compliant designs can improve product quality, durability, and market competitiveness. they help to meet the requirements of different markets. This is a favorable design direction for R&D engineers.

Enhanced product durability

The IP67 waterproof standard requires products to be able to operate in harsh environments of rain, sandstorms, etc. This helps to increase the durability and reliability of the product. And reduces the number of failures caused by environments.

Expanded market applications

IP67-compliant products can often be used in a wider range of market segments. Including outdoor, military, industrial, and underwater applications. This helps to expand the product’s market share and sales opportunities.

Enhanced product image

A product with IP67 waterproof certification is often considered to be of high quality and reliability. Thus, enhancing product image and market competitiveness.

Improved user experience

The IP67-certified product can often be used in a wider range of environments. Provide a better user experience. For example, cell phones with IP67 waterproof are designed to allow users to use them in rainy. Or a humid environment without worrying about damage.

Compliance with regulations and standards

Some markets and industries require to meet specific dust and water resistance standards to ensure safety and reliability. IP67 waterproof can help R&D engineers meet these regulations and standards.

How to choose the best IP65, IP66, IP67, IP68 for your product applications?

Depending on the specific applications and usage environments of your products. We also need to fully analyze and test it before selection. To ensure that the product can achieve the required dustproof and waterproof in actual usage. Here are some of our recommended considerations, which help you decide which dustproof and waterproof is best for your products.

Environment of use

Consider the environment in which will use your products. For example, if expose your products to rain and wind outdoors. Then a higher waterproof rating (e.g., IP67 or IP68) may be more appropriate. If place your product indoors and will not expose it to direct water or dust, then a lower rating (e.g. IP65 or IP66) may be sufficient.

Intended exposure

Consider the extent to which your products will be exposed to water, moisture, dust, etc. If your products are likely to be immersed in water for a short time, then IP68 may be a better choice. If there is only a slight chance of rain, wind, or splashing, then IP65 or IP66 may be sufficient.

Cost and complexity

In general, increasing dustproof and waterproof ratings will certainly increase the cost of designing and manufacturing. Higher ratings typically require more sealing materials and engineering, which can increase manufacturing costs. Therefore, you have to find a balance between cost and performance.

User needs

It is also important to understand user needs and expectations. If the user is more concerned about the waterproof performance of your product. Selecting a higher waterproof rating may be more appropriate. If your product is less likely to be affected by water or dust in use, then a lower rating may be considered.

Industry standards and regulations

Certain industries and markets may have specific standards and regulatory requirements. For the dust and water resistance of your products, It is important to meet these requirements.

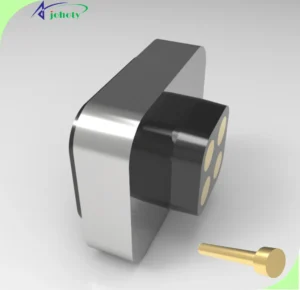

Best Inner Structure of IP67 Waterproof

IP67 waterproof pogo pin connector is to protect connecting cables and plugs from water, and dust in harsh environments. Need to ensure good sealing, durability, electrical performance, and safety. Its internal construction should utilize high-quality insulation and shielding. it is to meet the requirements and provide easy operations of connecting and disconnecting.

Sealing design

One of the most important structures is good sealing performance. This includes high-quality seals or gaskets to ensure that the connector interface is completely sealed. The sealing performance should meet the IP67 waterproof standard. That is when immersed in water one meter deep for up to 30 minutes, the pogo pin connector can still maintain a seal.

Durability

The pogo pin connector shell is made of strong materials, such as metal or high-strength plastic, to ensure that it will not be damaged in a harsh environment for a long time. The shell should have resistance to impact, corrosion, and UV.

Plug and socket design

Plugs and sockets should have the correct shape and structure. It is to ensure that they can only be correctly plugged together to avoid incorrect plugging. In addition, the connection of plugs and sockets should have a strong mechanical locking mechanism. This is to prevent them from accidentally falling off during use.

Internal insulation

The interior of the pogo pin connector should be equipped with high-quality insulating materials. It is to prevent short circuits between wires and cables. The insulation should also be moisture-resistant to ensure that the internal electrical components are protected from moisture.

Shielding and EMI protection

Some applications may require a Pogo pin connector to protect from electromagnetic interference (EMI). c This helps to maintain the stability and reliability of the connection.

Ease of connection

The IP67 waterproof pogo pin connector should be designed with ease of connection and disconnection in mind. This is very important for the user, especially in harsh environments. Wearing gloves or a limited line of sight under the IP67 waterproof connector can still be easily used.

Safety

The IP67 waterproof pogo pin connector should be designed with safety in mind. It is to ensure that the electrical connection is stable and not easy to loosen. This is very important to prevent short circuits and electrical failures.

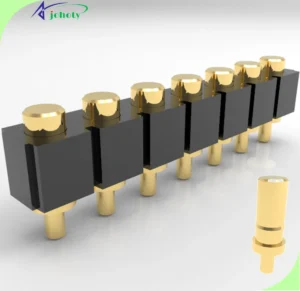

A variety of connection

IP67 waterproof connectors can provide a variety of connection methods. Such as DIP pogo pins, SMT pogo pins, and threaded, or anti-rotary locking. which are to meet the needs of all kinds of applications.

IP67 waterproof connectors in seawater, what problems are faced, and how to solve them?

Seawater salinity, pressure, and other environmental factors can cause additional stress and corrosion risk to IP67 waterproof connectors. Special considerations are given to raw material selection, design, and maintenance. Which is to ensure that the IP67 waterproof connectors work reliably under these harsh conditions.

Saltwater corrosion

Salt in seawater can corrode pogo pins in IP67 waterproof connectors, and shorten the life cycles of connectors.

Solution: Use corrosion-resistant materials to manufacture IP67 waterproof pogo pin connectors. Such as stainless steel, titanium, or special alloy materials.

Water pressure and water depth

The deeper the seawater, the greater the water pressure. Which may affect the sealing performance of the connector.

Solution: Design a stronger sealing system to ensure that the seal is in even under high pressure.

Bio-adhesion

Microorganisms, algae, and other organisms in seawater may grow on the connector and affect its function.

Solution: Use anti-bio-adhesion coatings, or clean and maintain the connectors regularly.

Temperature changes

Changes in seawater temperature may affect the material and sealing performance of the connector.

Solution: Use materials that can withstand temperature changes, and test the IP67 waterproof connector’s performance at different temperatures.

Electromagnetic interference

In seawater environments, IP67 waterproof connectors are susceptible to electromagnetic interference.

Solution: Use shielded designs to minimize electromagnetic interference.

Mechanical Abrasion and Shock

Currents, waves, or undersea activity may cause mechanical abrasion or shock to the connector.

Solution: Enhance the mechanical strength and impact resistance of the IP67 waterproof pogo pin connectors.

Ease of operation

It can be very difficult to operate the IP67 waterproof connectors underwater. Especially when wearing scuba gear or heavy gloves.

Solution: Design easy-to-operate connectors that are easy to connect and disconnect even when wearing scuba gear.

How to maintain and take care of IP67 waterproof equipment?

With regular maintenance, you can extend the life cycle of your equipment and ensure its performance well in harsh conditions. If find any damage or problems, please immediately repair or replace it to maintain its waterproof performance well.

Regular Cleaning

It is a very important step to regularly clean your device enclosure and IP67 waterproof connectors. Gently wipe the device with warm water and a neutral detergent. It is to ensure that you remove dust, dirt, and deposits from the device’s surface. Avoid using strong acids, alkalis, or caustic cleaners as this may damage the seals and housing materials.

Check seals

Periodically check that the device’s seals or gaskets are intact. If find any wear, cracks, or damage, replace the seal immediately. The integrity of the seal is critical to the waterproofing of the device.

Avoid hard impacts

The device’s housing should be left intact. Is protected from violent shocks or impacts that could damage the housing or IP67 waterproof connectors. Any external damage may reduce the waterproof performance of the device.

Correct connection

Ensure that correctly connect and securely lock the plugs and sockets of the device. Do not force connections or disconnections to prevent damage to IP67 waterproof connectors or seals. Make sure the device is in a dry condition when connecting and disconnecting it.

Avoid excessive twisting

Do not bend the cable excessively to prevent damage to the insulation inside the cable. Damage to the insulation may affect the electrical performance and water resistance of the device.

Keep dry

Try to avoid prolonged immersion of your device in water or a wet environment. Especially if your device is not designed for prolonged underwater use. Dry the equipment as soon as possible after it has been exposed to water and then dry it thoroughly.

Follow the manufacturer’s recommendations

Read the user manual of the device or the maintenance guide provided by the manufacturer. And follow the recommendations therein for maintenance and care. Different devices may have different maintenance needs. So it is important to follow the manufacturer’s recommendations.

Periodic inspection

Test the waterproofness of your device periodically to ensure that it still meets the IP67 standard. You can do it well by immersing the unit in water and checking that no water enters the unit.

IP67 Waterproof Use Cases

IP67 waterproof connectors play a key role in solving many industrial and commercial problems due to their advanced protection. It helps all types of equipment to adapt and work stably in a variety of extreme and challenging environments.

Outdoor Communication Devices

Problem: Such as, we always place wireless routers and signal amplifiers in harsh environments. so, need to protect them from water and dust to ensure proper operation.

Solution: Use IP67 waterproof connectors to ensure that the device interfaces are completely waterproof and dustproof. This ensures that the devices can operate stably even in heavy rain or sandstorm environments.

Industrial Automation

Problem: In automated production lines, both robotic arms and sensors need to operate stably in high humidity and dusty environments.

Solution: IP67 waterproof connectors connect sensors and control systems. Protecting the connection points from moisture and dust. This increases the reliability of the production line and reduces maintenance costs.

Marine Equipment

Problem: Vessels and other offshore equipment are susceptible to corrosion and water. Which easily damages the connectors in their electronic equipment. Because of prolonged exposure to seawater.

Solution: Use IP67 waterproof connectors to provide long-term waterproofing and corrosion. It ensures that equipment maintains its performance well even in wet marine environments.

Outdoor LED Lighting

Problem: Outdoor LED lighting systems need to operate in variable weather. Including heavy rain and high humidity.

Solution: The IP67 waterproof connector ensures a secure connection between the LED luminaire and the power supply. Preventing moisture intrusion that could lead to circuit shorts or other electrical failures.

Agricultural equipment

Problem: Modern agricultural equipment such as automated irrigation systems and sensors are often exposed to water and dirt. They are susceptible to damage.

Solution: The use of IP67 waterproof connectors ensures complete sealing of equipment interfaces. Preventing water and soil from damaging electronic components. Increasing the durability and reliability of this equipment.

What are the market trends and innovations for IP67 waterproof connectors?

Market growth

The IP67 waterproof connector market is continuing to expand as electronic equipment increases. Especially in automotive, industrial automation, medical equipment, communications, and outdoor equipment. The market is driven by the growing demand for dustproof and waterproof connectors with high reliability and resistance to harsh environments.

Technological innovation

Higher performance standards: In addition to the basic IP67 waterproof. New connectors may integrate more advanced protection standards. Such as IP68 or IP69K for more extreme environments.

Miniaturization and lightweight: To accommodate portable and space-constrained devices. IP67 waterproof connectors are evolving to be smaller and lighter.

Intelligent: Integrated sensors or data transmission enable connectors to not only provide physical connections but also data monitoring and intelligent control.

Innovations in raw materials and designs

Corrosion-resistant materials: more corrosion-resistant, high and low-temperature-resistant materials to improve the durability and reliability of the connector.

Modular design: The modular and customizable design makes the IP67 waterproof connector more flexible to adapt to various applications.

Eco-friendly trends

With the enhancement of environmental awareness, we tend to consider environmental factors during the design of IP67 waterproof connectors. the use of recyclable materials, and reduce the use of hazardous substances.

Expansion of application areas

With technological advances, IP67 waterproof connectors are expanding in new application areas outside of traditional fields, such as wearable devices, drones, etc.

Intelligent manufacturing and supply chain optimization

We are adopting more advanced production technologies and supply chain management strategies. The target is to improve productivity and reduce costs.

Conclusions

IP67 waterproof connectors not only represent the top standard for protection and durability but their importance and versatility are increasing. With continued technological innovation and expansion of applications.

With a variety of practical application cases, we have seen how IP67 waterproof connectors ensure the stable operation of equipment in harsh environments. At the same time, it enhances the reliability and efficiency of the overall system. Demonstrates its excellent performance.

As market demand grows for higher-performance, smaller, and more eco-friendly products. We can foresee that IP67 waterproof connectors will continue to play a key role in design innovation and technological advancement. It plays a central role in the field of electronic connection technology.

So, for IP67 waterproof connector, we suggest:

About IP67 waterproof connectors of solutions, characteristics, applications, or technical details, please contact us.

If you want to how our IP67 waterproof connectors can meet your specific requirements. Please contact us for samples or quotes of IP67 waterproof connectors.