What is a Test Probe?

Test Probe, Reliable Precision, Various Shapes Available, Excellent Performance for Engineers and E-expert. Perfect IC/ICT/FCT Pogo Pins! Custom!

IC test probe connects contacts between test equipment and chip pins for chip tests. Performs functional tests, electrical performance tests, reliability tests, etc. The ICT test probe is a comprehensive electrical and partial functional test. FCT test probe is a comprehensive functional and performance test for the entire product. Applied to different stages of electronic product manufacturing and testing requirements.

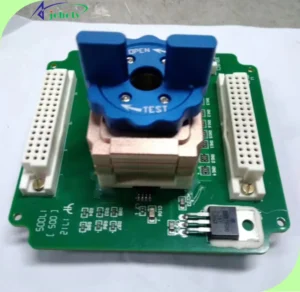

IC test probe

It tests and verifies IC chips. Includes functional, electrical, and reliability tests.

Its categories include solder ball test probe, pressure test probe (pogo pins), blade test probe, micro pin test probe, bending test probe, fixed test probe, and RF test probe.

Usually made of brass, tungsten, tantalum, and silver. it has a stable electrical conductivity and perfect corrosion resistance. CAN Ensure reliable electrical connection.

Widely used in semiconductor manufacturing, electronics production, and R&D. It tests various types of IC chips, including integrated circuits (ICs), microprocessors, memories, sensors, and so on.

ICT test probe

ICT test probes test the electrical connectivity of electronic components on a PCB. but can also perform a wider range of functional tests. Including checking component parameters, testing communication interfaces, and measuring voltages, currents, and waveforms.

It is typically in the middle stages of electronics manufacturing. It ensures a basic electrical performance and functionality of the electronic product.

FCT test probe

FCT test probe tests the functionality and performance of entire electronic products. Verifies that the product works properly according to specifications, including functionality, performance, interfaces, and interaction with other systems. Typically performed in the later stages of electronics manufacturing to ensure the quality and performance of the final product.

IC test probe Features

It is a key component in the semiconductor manufacturing and testing process. It has many specific product characteristics.

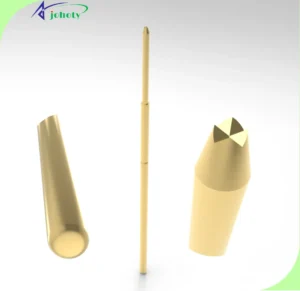

Plunger Tip

Its plunger tip is often very small to ensure precise connection to the chip’s pins or test points. Including sharp, crown, round, cup, flat, dome, and custom shapes for two ends. Designed to accommodate different shapes, densities, and spacing of test points.

Conductive raw materials

Made of highly conductive materials such as brass, tungsten, tantalum, and silver. These materials ensure a good electrical connection.

High durability

High wear resistance, especially in high-production volume test environments. A wear-resistant IC test probe can greatly reduce the frequency of replacement.

Spring Force

Enough spring force can make steady contact with the test point during the test. Spring stiffness, spring force, and life cycles are all important.

Temperature stability

It needs to have good temperature stability to maintain a reliable connection when testing in a high or low-temperature environment

High-frequency performance

For radio frequency (RF) testing, some IC test probes have optimized high-frequency performance to ensure accurate signal transmission.

Automation compatibility

IC test probe is for use with Automatic Test Equipment (ATE) to support high-speed, high-precision automated tests..

Safety

Special designs prevent short circuits or other electrical problems.

Cost-effect

Controlling costs is important for mass production

ICT test probe Features

The product features are mainly reflected in its design, function, and application in circuit board tests. It realizes high-precision and high-efficiency circuit board tests. While taking into account ease of operation and test reliability. These features make it an important quality control tool in the electronics manufacturing industry.

Precision contact design

It has very fine tips that make precise contact with specific test points on a circuit board, such as pads or pins.

Ensure a reliable electrical connection for accurate measurements.

High-density layout compatibility

As electronic component sizes decrease and board densities increase, It can accommodate high-density circuit layouts.

Can effectively access and test circuits in a very small space.

Customized Fixtures

ICT test probe often requires customized test fixtures designed for each specific circuit board.

These fixtures contain multiple ICT test probes that contact multiple points on the board at the same time.

Overall circuit testing capabilities

Can detect a variety of problems on a circuit board. Including open circuits, short circuits, incorrectly mounted components, incorrect component polarity, and more.

Achieved the test by testing the electrical characteristics of the circuit.

High-speed testing capabilities

ICT test probe can rapidly test and is suitable for batch testing on production lines.

This helps to increase productivity and reduce testing time.

Stability and Durability

For a large number of test cycles, the ICT test probe usually has high stability and durability.

Take into account the wear and tear of its raw materials over a long time.

Optimization of electrical characteristics

Takes into account their electrical characteristics, such as impedance matching. It is to ensure the accuracy and reliability of the test signal.

FCT test probe Features

Its features focus on its functionality and are for testing the overall functionality and performance of the UUT.

Simulate actual operating conditions

FCT test probe is to simulate the conditions of a circuit board in its actual operating environment and verify that it functions as designed.

This testing typically involves the simulation of power inputs, signal outputs, and other actual operating conditions.

Versatility test capability

The ability to test the circuit board’s multiple functions. Such as power management, signal processing, microprocessor performance, and so on.

In this way, it ensures that the board is not only physically complete but also being on functional.

Complex test procedures

FCT test probe typically involves more complex test procedures and algorithms than the physical connection inspection of ICT tests.

This may include software-controlled test procedures to simulate different operating conditions and environments.

Customized test fixtures

Depending on the specific function and design of the board. The customized test fixtures with FCT test probes can ensure proper board placement and contact for full functional tests.

A high degree of flexibility

For a higher degree of customization and flexibility, it relates to the specific functionality of the board.

This makes FCT testing ideal for complex boards or special applications that standardized ICT tests can’t cover.

Feedback and diagnostic information

FCT testing provides detailed feedback and diagnostic information about the board’s performance. Helping to identify potential problems in the design. This is essential for debugging and optimizing board designs.

Suitable for low volume and customized production

Due to the complexity and degree of customization of its tests and the test fixture with the FCT test probe. It is suitable for low-volume production or customized circuit board tests.

What Shapes Do IC/ICT/FCT Test Probe Have? What Problems Can They Solve?

Test probes are available in a variety of plunger tip shapes for different test probes and their solutions.

30° Plunger Tip

For high-precision contacts, especially in space-constrained applications. Suitable for small pads or closely spaced pins. For less than 30°, it is for very precise contact. Such as micro-solder pads or high-density integrated circuits. It can ensure good electrical contact.

Flat Plunger Tip

Provides a larger contact area for larger solder pads or test points. It can reduce wear on test points.

Inverse Cone

Ideal for testing pads, especially with rough or uneven surfaces

4-Point Crown

Provides good contact, especially suitable for solder pads and multilayer board PCB.

Bullet-Nosed

It is for round or irregular test points to provide stable contact.

Serrated

Ideal for applications of piercing oxidized layers or other contaminants, providing good contact and penetration.

Flexi Plunger Tip

Ideal for applications of consistent contact at varying pressures.

Flat with 45° Chamfer

Combines the advantages of flat plunger tips and chamfers. It is for a large contact area without damaging the test point.

Advantages of IC/ICT/FCT Test Probe

IC Test Probe

High-density Testing. High-density arrangement to accurately test each solder ball.

Inline testing. Integrate into ATE to enable online and improve testing efficiency

High-temperature testing: They have high-temperature testing capabilities, and can work in high-temperature environments. It is to ensure the reliability of IC chipsets under extreme conditions.

Long life and wear resistance. They are usually made of high-quality materials with a long service life and good wear resistance. This is important for continuous production and testing.

Auto-calibration. The test probe has an auto-calibration feature that can calibrate itself periodically to ensure test accuracy.

Customizability: Depending on the specific IC package and testing requirements. We can customize different types of IC test probes, including different sizes, materials, and shapes.

ICT Test Probe

High speed. Very fast, test multiple components on a board in a short time. This makes it very suitable for environments with large-scale production.

High accuracy. They provide highly accurate test results and can detect minute electronic component defects and faults.

Automation. ICT test probe can be integrated with ATE for a highly automated test process. This reduces the need for manual intervention and improves test efficiency and consistency.

Time and Labor Saving: Saves time and labor resources, and reduces testing costs compared to manual testing methods.

Customizability: ICT test solutions can meet the requirements of specific electronic components and boards. This means that test programs can be flexibly adapted to different test requirements.

FCT Test Probe

Comprehensive testing. Can test an entire electronic product, including hardware and software functionality. This makes it possible to comprehensively assess whether a product meets design specifications and customer requirements.

Troubleshooting: Can identify and troubleshoot faults and problems in a product. Including electronic component failures, connectivity issues, circuit failures, and more. This helps to improve product quality and reliability.

Final Verification: Verify the final product quality. It ensures that safely deliver the products to the customer. It helps in reducing the cost of product returns and repairs.

Conclusions

The above article introduces you to the benefits, features, type selection, and product advantages of IC, ICT, and FCT test probes. It illustrates the importance of quality products and services.

We can customize the most reasonable solutions for your requirements. We truly recognize the importance of customer feedback and would love to hear from you.

In the meantime, we are sure to offer you the best price and quality for the test probe you are looking for. We hope to establish a long-term cooperation!