Choosing the correct type of gas spring among various products is quite a task. Often, users don’t know about the broad applications of a gas strut. It isn’t easy to understand the uses of a gas spring. What are the gas strut types? And much more.

Through this guide, we will help you choose the right type of gas spring according to the application. Moreover, don’t forget to look at the Gas Spring CatLog and choose as per your requirement for furniture, cars, or other uses.

What is a Gas Spring?

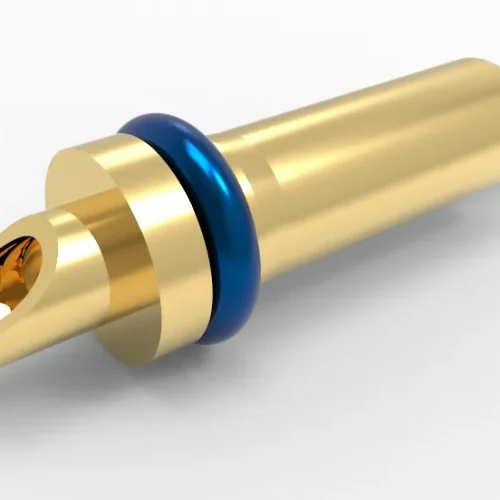

A gas spring is a mechanical device that uses the compressed gas in a cylinder to exert force and provide motion control. The main components of gas props are a Cylinder, A piston, a piston rod, a seal, a valve, and a guide. Nitrogen gas filled in the cylinder. Also, a gas strut or a gas lift that has various applications to offer the following services:

- Lifting

- Lowering

- Counterbalancing and more

A gas spring works on the basic principle of using nitrogen gas as an electric medium with oil for sealing, lubrication, and transmitting pressure. The principle is based on Boyle’s law. The spring offers a maximum force, such as 12000N. With a wide range of designs and dimensions, the device has no external power supply needs. Further, the springs operate without noise and at an opening angle.

It uses compressed gas to maneuver different parts of a piston rod and a cylinder, creating a strong force. The force is directly proportional to the increase in pressure. Moreover, even the smallest spring can generate impressive force for weight lifting and other activities.

Types of Gas Springs

Certain types of designs and sizes are available in the market. Different types of gas springs have been used in different industries.

Here we share a few of the types that include:

1: Standard

This comes with a rod attached to a piston within a sealed cylinder. It is the most compact and reliable type of gas spring that is more useful in lifting and counterbalancing applications.

2: Adjustable

Another type of spring that features a fantastic characteristic. The stroke can lock it at any position. Moreover, the rod operates as a compression gas. So, it releases the plunger at any point.

3: Variable

The variable spring has wide use in the house and car doors. It has a dual cylinder that relates to a hydraulic valve. By pushing motion, the hydraulic gas strut cylinder creates damping.

4: Custom

Custom springs are used in different industries. They are available in materials such as EPDM, Viton, polyurethane, etc.

5: Tension and Traction

Tension and traction spring offers tension on the belt drive and mechanical assemblies. This type of gas prop cylinder is available in various sizes and stroke ranges- The variety of size ranges aids in choosing the proper force range and k factors for the use. Moreover, the springs have a distinctive design with stainless steel.

6: Stainless steel

Stainless steel springs have a characteristic that they are perfect for corrosive environments. Additionally, they come with a release valve that helps during the operation by releasing gas upon the direct force.

Applications of Gas Springs

One of the many applications of springs is controlled motion. The spring offers controlled motion and harmonic balance while moving objects.

Gas spring applications cover the following industries: automation, aerospace, pharmaceuticals, furniture, and other industries.

In addition, the list of its applications is quite long. However, here are further its uses:

- Standard gas spring has various uses in agriculture and industrial equipment, adjusting chairs, recreation of vehicles, and cargo trailers

- Adjustable springs have wide use in hospital beds. Further, furniture, passenger seats, and emergency casualty trolleys also have gas struts.

- Custom gas springs are perfect for UAV launchers and MRI machines.

- Furthermore, the springs have extensive applications in LCD support, medical equipment, and automotive tools.

The gas springs are standard in aerospace industries, oil dampeners, and truck tailgates. Moreover, their applications are open to more than the areas mentioned above.

Let’s look at how different industries need different types of springs.

i. Automotive:

Gas springs in car hoods, trunks, and tailgates help users lift and lower these heavy parts quickly.

ii. Furniture:

Springs are employed in office chairs to adjust the height and reclining chairs and beds for adjustable positioning.

iii. Industrial machinery:

They are used in industrial equipment for tasks such as lifting heavy machine covers or providing counterbalance in conveyor systems.

iv. Aerospace:

Aircraft widely use springs for applications such as holding cargo doors and supporting seating systems.

v. Medical Equipment:

Medical devices like hospital beds and examination tables often use gas springs to enable adjustable positioning and ease of use.

vi. Campers:

Gas springs are used in recreational vehicles and campers for tasks like lifting compartment doors and supporting foldable parts.

Final Verdict:

A gas spring is one of the much-needed maintenance tools for automotive, medical, pharmaceutical, aerospace, and other industries.

Further, the essential function of lifting heavy objects by using stainless-steel gas props can’t be neglected. According to the advised use, one must be careful when choosing the right spring design.

Suppose you are looking forward to finding a gas spring; search for a spring near me and find the locations of stores. Lastly, you will find excellent options of light to heavy-duty springs on sale.