What Is Soldering? Explore How this Crucial Process Enhances Your SMT Mounting of Pogo Pin Connector and Its Benefits in Electronic Assemblies

Introduction: What Is Soldering, the Basics and Importance of Soldering

What Is Soldering, Soldering is a process that securely joins two or more metal surfaces by heating and melting solder. It’s essential to today’s electronics, especially in SMT production. In SMT, soldering is key to ensuring that electronic components are reliably connected and operate smoothly. It not only creates a strong mechanical bond but also establishes a low-resistance electrical path, which boosts performance and durability.

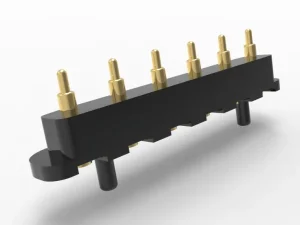

As electronics get smaller and stronger, soldering has become key in production. It allows for precise placement of tiny components, such as Johoty’s Pogo Pins or Pogo Pin Connector, onto printed circuit boards (PCBs), ensuring stable, long-lasting connections. This process reduces the likelihood of device failure and significantly improves assembly efficiency, driving down overall production costs.

Understanding the principles of soldering and its application in SMT is essential for manufacturing high-quality electronics. This is especially true when using high-precision, reliable connectors like Johoty Pogo Pin Connector, where soldering is a must-have step.

Types of Soldering and Their Role in Electronics Assembly, What Is Soldering

In electronics assembly, SMT soldering for Pogo Pin Connector is a key step in achieving efficient connections. Soldering generally falls into two categories: soft soldering and hard soldering. For SMT applications, soft soldering is preferred due to its lower operating temperatures and adaptability to various materials:

1. Soft Soldering: What Is Soldering

- Soft soldering is the most common technique in SMT. It typically uses tin-based alloys as solder. The main advantage of this method is its low temperature (ranging from 180°C to 250°C), which prevents heat damage to electronic components. For Johoty’s Pogo Pin Connector, soft soldering ensures stable electrical performance while maintaining mechanical integrity during the soldering process.

- Use Cases: In consumer electronics (like smartphones and tablets) and industrial automation equipment, soft soldering of Pogo Pin Connector ensures components are securely attached to the PCB, maintaining long-term electrical contact. Its fast cooling and resistance to thermal shock make it highly popular in these fields.

2. Reflow Soldering: What Is Soldering

- Reflow soldering is a common soft soldering technique used in SMT. It involves heating pre-applied solder paste on components to melt and bond them to the PCB. During reflow soldering, Johoty’s Pogo Pin Connector achieves precise and stable connections thanks to the even distribution of solder paste and accurate temperature control.

- Application: Reflow soldering is widely used in high-volume automated production lines, such as in automotive electronics and medical devices. This process allows Pogo Pin Connector and other surface components to be soldered simultaneously, boosting production efficiency and ensuring the reliability of every connection.

3. Selective Wave Soldering: What Is Soldering

- In PCB assembly involving both SMT and THT (Through-Hole Technology) components, selective wave soldering is a key process. It controls the molten solder to only touch areas that need soldering, avoiding interference with other surface-mounted components. Johoty’s Pogo Pin Connector can be soldered with this technique to ensure electrical performance while minimizing heat damage to the components.

- Application: This method is commonly used in complex electronics assemblies like communication devices and high-end industrial control systems, where Pogo Pin Connector must be efficiently and precisely soldered alongside other components. The high precision of selective wave soldering meets these demands.

4. Laser Soldering: What Is Soldering

- Laser soldering is an emerging high-precision technique that uses a focused laser beam to directly heat the soldering point, melting the solder to create a bond. Due to its precise local heat control, it is ideal for the precision soldering of Johoty’s Pogo Pin Connector, particularly in applications requiring tiny solder joints and complex circuit structures.

- Application: Laser soldering is commonly found in microelectronics and high-end medical device manufacturing. It ensures accurate alignment of Pogo Pin Connector with sensitive components while minimizing heat impact. This method not only enhances product reliability but also reduces thermal damage to surrounding components, extending the device’s lifespan.

By optimizing these various soldering techniques, Johoty’s Pogo Pin Connector performs at its best in diverse and complex SMT and electronics assembly environments. These methods ensure connection reliability, stable electrical performance, and production efficiency, providing significant benefits to customers across multiple industries.

Soldering Process Steps and Compatibility with Johoty Pogo Pin Connector, What Is Soldering

In electronics assembly, SMT (Surface Mount Technology) soldering is a key step for connecting Pogo Pin Connector to PCBs (Printed Circuit Boards). This process requires exact precision and speed while keeping solder joints stable and reliable over time. To better understand how soldering enhances the performance of Johoty Pogo Pin Connector in SMT installations, here are the detailed steps of SMT soldering and the product’s compatibility at each stage.

1. Preparation Phase: PCB and Component Pre-Treatment

- Before starting the soldering process, the PCB surface must be clean and smooth, with a precise application of solder paste on the pad areas. Thanks to Johoty’s high-precision size control, Pogo Pin Connector aligns perfectly with the PCB pads, ensuring accurate solder joint placement. Additionally, the anti-oxidation treatment on Johoty products prevents oxidation before assembly, improving solder bond strength.

- Compatibility Features: Johoty Pogo Pin Connector has a smooth, oxidation-resistant surface, ensuring optimal bonding with the solder paste during the process, and enhancing joint strength and conductivity.

2. Solder Paste Printing and Component Placement

- Solder paste printing involves applying solder onto the PCB pads using a stencil. The even distribution of solder paste is critical for solder quality. At this stage, Johoty’s Pogo Pin Connector, with their optimized base design, ensure that solder spreads evenly upon contact. Their high-precision dimensions also guarantee accurate component placement, preventing misalignment or shifting.

- Compatibility Features: The base design of Johoty Pogo Pin Connector ensures strong compatibility with solder paste, promoting even distribution and better soldering results, while their precise geometry ensures accurate placement during assembly.

3. Reflow Heating: Solder Melting and Bonding

- Reflow soldering is the most critical step in SMT, where the assembled PCB is passed through a heating zone to melt the solder paste, bonding the components to the PCB pads. At this stage, Johoty Pogo Pin Connector demonstrates exceptional thermal stability and resistance to heat shock, handling rapid temperature changes from room temperature to 250°C. Their material selection and surface treatment ensure the metal doesn’t deform or detach during soldering, forming a solid electrical connection.

- Compatibility Features: Johoty Pogo Pin Connector uses heat-resistant materials that easily withstand the high temperatures of reflow soldering, maintaining mechanical strength and electrical performance with no cold joints and uniform soldering.

4. Cooling and Solder Joint Solidification

- The cooling phase after reflow is critical, as the solder transitions from liquid to solid, forming the final solder joint. The cooling rate affects the mechanical strength and electrical stability of the joint. Johoty Pogo Pin Connector, with their unique material properties, effectively prevent cracks or stress concentration during cooling, ensuring long-term durability of the solder joints.

- Compatibility Features: Johoty Pogo Pin Connector exhibits excellent resistance to thermal stress during cooling, ensuring that the solder joints aren’t damaged by temperature differences. The resulting joints are strong and free from long-term risks.

5. Post-Soldering Inspection and Functional Testing

- After soldering, all joints undergo visual inspection, X-ray scanning, and electrical function tests to verify quality and connection reliability. Johoty Pogo Pin Connector, with their precise design and stable materials, show extremely low resistance, stable conductivity, and pass rigorous quality checks.

- Compatibility Features: Johoty Pogo Pin Connector, backed by a strict quality control system, ensure that each solder joint delivers optimal performance in testing, with stable conductivity and virtually no solder defects.

Throughout the entire SMT soldering process, Johoty Pogo Pin Connector exhibits high compatibility and reliability. From preparation to final testing, their precision, heat resistance, and anti-oxidation properties ensure efficient and stable electronics assembly. This makes Johoty products ideal for a wide range of industries, significantly improving production efficiency and assembly quality in manufacturing.

Why Choose Johoty’s Pogo Pin Connector for SMT Soldering? What Is Soldering

When selecting a Pogo Pin Connector for Surface Mount Technology (SMT) soldering, Johoty’s products stand out due to their exceptional performance, reliability, and versatility. Whether for high-precision industrial equipment, consumer electronics, or complex medical devices, Johoty’s Pogo Pin Connector offers stable and efficient solutions with unique advantages:

1. High Precision and Wide Range of Specifications

- Johoty Pogo Pin Connector is known for its high-precision manufacturing, featuring strict dimensional tolerances to ensure a perfect fit with PCBs during soldering. This precision guarantees tight contact at every solder point, reducing the risks of cold or misaligned joints. Additionally, Johoty offers a variety of sizes and specifications to easily fit different PCB layouts and installation needs, making their products suitable for applications ranging from consumer electronics to industrial automation.

- Key Advantage: What Is Soldering, High-precision dimensions and diverse specifications make Johoty Pogo Pin Connector ideal for accurate and reliable installations across various projects.

2. Outstanding Thermal Stability and Soldering Compatibility

- SMT soldering often involves high temperatures, especially during reflow, where soldering temperatures can reach up to 250°C. Johoty’s Pogo Pin Connector is made from heat-resistant materials and undergo specialized surface treatments to prevent deformation, oxidation, or loss of electrical performance in high-temperature environments. This excellent thermal stability ensures that the soldered connections remain strong and conductive, minimizing the risk of soldering failures.

- Key Advantage: What Is Soldering, Superior heat resistance and material compatibility enable Johoty Pogo Pin Connector to withstand various SMT soldering conditions, ensuring stable and reliable electrical connections at every solder point.

3. Highly Reliable Electrical Connection Performance

- The core function of a Pogo Pin Connector is to provide a reliable electrical connection, and Johoty’s products ensure stable current flow and low contact resistance through high-quality materials and innovative design. Even under prolonged use or extreme conditions, Johoty’s Pogo Pin Connector maintains excellent conductivity, ensuring smooth operation of devices. This high level of reliability is especially ideal for applications like medical equipment and automotive electronics, where long-term stability is crucial.

- Key Advantage: What Is Soldering, Exceptional conductivity and long-lasting stability make Johoty Pogo Pin Connector the perfect choice for demanding electronics projects.

4. Strong Oxidation and Corrosion Resistance for Harsh Environments

- Johoty’s Pogo Pin Connector is treated with advanced oxidation and corrosion-resistant technologies, allowing them to perform consistently in tough environments. This makes them ideal for industrial automation, outdoor equipment, and other applications exposed to high humidity, corrosive gases, or dust, while maintaining reliable electrical connections and mechanical strength.

- Key Advantage: What Is Soldering Superior oxidation and corrosion resistance ensure Johoty Pogo Pin Connector remains highly stable even in harsh environments.

5. Custom Solutions to Meet Specific Needs

- Every project has unique design requirements, and Johoty offers comprehensive customization services. They can tailor Pogo Pin Connector to specific client needs in terms of size, shape, and material selection, ensuring the product perfectly fits the project. This flexibility not only enhances product compatibility but also helps customers save development and production time, optimizing project costs.

- Key Advantage: What Is Soldering, Flexible customization allows Johoty Pogo Pin Connector to be tailored to client specifications, making them a perfect fit for any project.

6. Boosting Production Efficiency and Reducing Assembly Costs

- Johoty’s Pogo Pin Connector is designed with efficient automated production in mind, integrating seamlessly into SMT automated soldering lines. Their consistent quality and quick installation reduce welding issues and rework, significantly increasing production efficiency. Additionally, with long-term stability and durability, Johoty’s Pogo Pin Connector helps customers lower long-term maintenance and replacement costs.

- Key Advantage: What Is Soldering, High production efficiency and low maintenance costs make Johoty Pogo Pin Connector a cost-effective choice in electronics manufacturing.

Choosing Johoty’s Pogo Pin Connector for SMT soldering not only improves assembly efficiency and electrical performance but also ensures long-term stability and reliability across various applications. With their precision, durability, customization options, and adaptability to harsh environments, they are an ideal solution for complex project needs. By selecting Johoty products, your factory will achieve higher production efficiency, lower costs, and gain a competitive edge in the market.

Conclusion: Future Trends in Soldering Technology and Johoty Pogo Pin Connector Innovations

As electronic devices evolve rapidly, soldering technology is advancing towards greater efficiency, precision, and environmental sustainability. This shift not only meets the increasingly complex design demands of consumer electronics but also provides more reliable solutions for sectors like medical, automotive, and industrial automation. In this context, SMT soldering continues to evolve, and Johoty’s Pogo Pin Connector keeps pace with these trends by driving innovation and expanding application possibilities for the future of soldering technology.

1. Miniaturization and High-Precision Soldering Trends

- As electronic devices become smaller and more integrated, solder joints are shrinking, posing higher challenges for soldering precision and processes. Future soldering technologies will focus on achieving micron-level precision to ensure stable electrical and mechanical connections within tiny soldering areas. Johoty’s Pogo Pin Connector, with their outstanding miniaturization and precise manufacturing, already meet these ultra-high precision soldering needs. By continually optimizing the structure and materials, Johoty ensures top performance even in miniature devices.

- Forward-Looking Development: What Is Soldering, Johoty will continue advancing the miniaturized Pogo Pin Connector, further enhancing its ability to meet future ultra-precise soldering demands and offering innovative solutions to customers.

2. Lead-free soldering and Eco-Friendly Materials

- As global environmental regulations become more stringent, the electronics manufacturing industry is shifting towards lead-free soldering. Future soldering will focus on using greener materials to cut down on environmental impact. Johoty has already adopted eco-friendly materials in the production of its Pogo Pin Connector, ensuring full compatibility with lead-free soldering techniques. Through strict material selection and production control, Johoty’s Pogo Pin Connector not only meets environmental standards like RoHS but also enhances product performance and durability.

- Forward-Looking Development: What Is Soldering, Johoty will continue to invest in research on eco-friendly materials, ensuring that all its products comply with global environmental regulations and support customers in achieving green production goals.

3. Integration of Smart Welding and Automation Technologies

- Welding technology is evolving towards greater automation and intelligence. Future soldering lines will rely more on machine vision, artificial intelligence, and automated control systems to achieve higher efficiency and precision. Johoty’s Pogo Pin Connector is designed with compatibility for automated production lines, enabling efficient SMT installation and seamless integration with modern smart welding systems. By incorporating machine vision and automation, Johoty’s products will further improve in precision and production efficiency.

- Forward-Looking Development: What Is Soldering, Johoty plans to advance smart welding technologies and develop Pogo Pin Connector that is better suited for intelligent factories, helping customers significantly enhance production automation.

4. Combining Multiple Soldering Techniques

- The future of soldering will move beyond single techniques, integrating various methods like laser soldering, reflow soldering, and selective wave soldering. By combining these techniques, more complex circuit connections can be achieved on the same production line. Johoty’s Pogo Pin Connector is designed to be flexible and compatible with multiple soldering processes. Whether for small-scale custom production or large-scale automated assembly, Johoty’s products can adapt to different soldering needs, offering optimized solutions.

- Forward-Looking Development: What Is Soldering, Johoty will further optimize the compatibility of its Pogo Pin Connector with various soldering processes, ensuring they play a larger role in multifunctional soldering lines, providing customers with greater production flexibility.

5. Innovative Materials and High-Performance Soldering

- With the advancement of new material technologies, future soldering processes will increasingly incorporate innovative materials to achieve greater heat resistance, conductivity, and corrosion resistance. Johoty has been at the forefront of research and application of these materials, combining high-performance materials with advanced soldering techniques to further enhance the overall performance of its Pogo Pin Connector. This enables Johoty’s products to excel in extreme environments such as high temperatures, humidity, or corrosive conditions, providing long-lasting reliability and safety for clients across various industries.

- Forward-Looking Development: What Is Soldering, Johoty will continue to invest in new material technology, working with leading material scientists to further improve the comprehensive performance of Pogo Pin Connector, ensuring their leadership in future soldering technology.

The future of soldering trends toward higher precision, environmental sustainability, intelligence, and multifunctional integration. Through continuous innovation and keen insights into these trends, Johoty has laid a solid foundation for the ongoing development of its Pogo Pin Connector. Johoty not only leads in current soldering technologies but also demonstrates strong innovation in driving the future of soldering processes. Choosing Johoty’s Pogo Pin Connector is not only a guarantee of high quality for today’s projects but also a smart investment in the future of soldering technology.