What Is a High Current Connector?

The high current connector is to transfer a high current. It is an adaptor, male and female connector. It is often applied in electric vehicles, electronic devices, industrial, power, and transportation.

Due to the specificity of its application, it requires:

High current capacity

We can provide 3A~600A high current connectors. Also, we can customize some higher current connectors as per your requests.

High-Temperature Resistance

The major problems facing current high current connectors are temperature rise and galvanic corrosion. And low voltage temperature rise is the key to affecting the load capacity and reliability of the high current connectors.

Durability

High current connectors usually require good durability to withstand frequent plugging and unplugging and harsh environments.

Security

Due to the high currents involved, they often have to ensure a safe connection and protect against risks. Such as electric shock, fire rating, worker protection, etc.

Protection Level

As per their applications, need to protect the inside of the high current connector from dust, water, and other external environments

Connection Types

Secured with screws, anti-rotation locking. And pluggable and unpluggable male and female connection.

What Problems Do Customers Often Encounter?

Many customers possibly encounter some problems and challenges. Herein, we are always positive to reply to customers and propose the right solutions. We try our best to meet the targets of customers. At the same time, we also try our best to win customer’s trust and improve ourselves in competitive power. Through our continued innovation and technological improvement.

Compliance and certification?

We can provide high current connectors in European or American Standard, or based on customers,

Poor quality and reliability?

In the applications of high-current and high-voltage, we can make sure all are well.

High temperature?

Which will damage customer devices and equipment. We can effectively solve the temperature management and cooling issues well.

Hazardous working environments?

Customer’s devices or equipment work in various working environments. Including, high temperature, low temperature, humidity, and corrosion. We always think about the perfect design and the best raw materials to solve it.

Customization issues?

For customer’s special applications, we can customize various high-current connectors to meet the targets of customers.

Problems about sustainability, and eco-friendliness?

It is very important. Our high current connectors are compliant with all policies. Including, halogen-free, lead-free, RoHS, REACH, etc.

Hard to get the best offer, no cost-effective?

We always pay top attention to the high quality, best performance, best pricing, and cost-effective. It is our strength and strong power. Hope to do a long-term business.

Stable supply chain?

For a long-term business, we have a complete production process and a complete supply chain. We always adhere to very stable suppliers and effective supplier management.

Technical support and professional after-sale services?

A reliable engineering team and professional after-sale services are very important. We always are online and fully support our customers.

Why is the High Current Connector Helpful for R&D Engineers?

The high current connector is a valued component for R&D engineers. It can help greatly simplify and improve the R&D process. This helps R&D engineers focus more on innovation and the development of products. Which can greatly accelerate technological progress.

Lab test and prototype development

When R&D and T/R handle the high current of electric vehicles. Power systems, and high-performance electronic devices. The high current connector can provide R&D engineers with safe, reliable, and easy-to-operate power connections.

Safety improvement

Safety is always the most important. It has overheat protection, short-circuit protection, or anti-arc technology. Which greatly reduces risk in the workplace and protects R&D engineers and equipment.

Efficiency improvement

High current connectors can quickly and effectively transfer high current, and reduce power loss. And improve the overall energy efficiency of the test and R&D. which is very helpful for R&D engineers who focus on new energy and energy-saving devices.

Flexibility and Adaptability

We can customize high current connectors based on different applications. Such flexible design is greatly helpful for R&D engineers. Then, R&D engineers can optimize their designs based on the detailed project requirements.

Reduce R&D time

By providing reliable and efficient power solutions, the high current connectors help engineers reduce equipment failures and downtime. Which can minimize the time from concept to market.

Support for high-performance testing

In certain fields of fast charging for electric vehicles or large-scale energy storage systems, needs to fulfill the UUT test with high currents. Then, high current connectors play a key role here, ensuring stability and precision during testing.

Features of High Current Connector!

The high current connector has a high current capacity and low resistance. High-temperature resistance, corrosion resistance, dust proofing, and waterproofing. Safety, durability, and a wide range of types. It is easy to install and maintain with a wide range of applications.

It has a low contact resistance to support a high current capacity of up to 600A. Even, it can withstand a few thousand Amperes of high current. Its low resistance can minimize power loss and heat, ensuring highly effective current transformation.

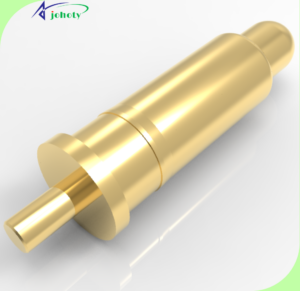

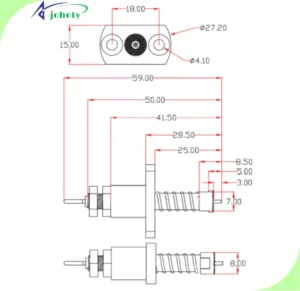

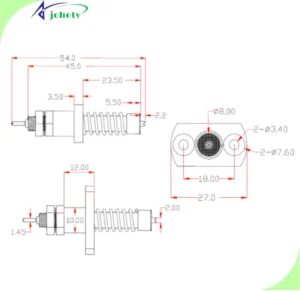

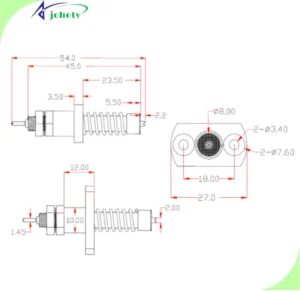

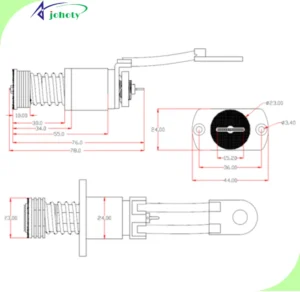

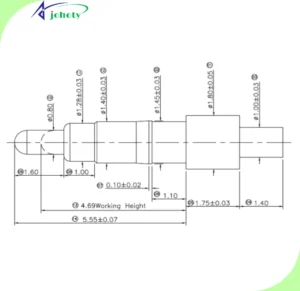

The high current connector has 2 or 4 holes to lock with anti-rotation. It is also available as a pogo pin structure without holes. Or as a pogo pin connector structure secured by a housing.

Various shapes of round, square, the high current connectors can adapt to the market. And so on.

Applications of High Current Connector!

This type of power transmission device is mainly used where high current transmission is required. Which demonstrates the importance of high-current connectors in modern industry and technology. Where they are essential to ensure the efficient and safe operation of critical facilities.

Industrial automation of high current connector

Provides a stable power supply to drive a variety of heavy machinery and equipment.

Giga factory of high current connector

It is very critical to produce batteries and other key components in giga factories.

Electric Vehicle Charging Stations of high current connector

Fast charging technology for electric vehicles requires high-current transmission. And, they play a key role in ensuring efficient and safe power transmission.

Data centers of high current connector

Servers and computing devices require a reliable power supply. High-current connectors can be used to ensure their continuous operation.

Renewable energy systems of high current connector

In the field of wind or solar power, they are used to manage and transmit high currents. From the power generation equipment to the energy storage system or the power grid.

Railroad systems of high current connector

High-current connectors are used to transmit power from the supply lines to the trains.

Heavy equipment of high current connector

In the construction and mining industries, excavators and cranes often require high currents to operate.

Use Cases: High Current Connector in Gaga Factory

Let’s introduce the applications of the high current connector in the Gaga factory. For example, the battery factory of Tesla. It is very critical. Because the high current connector is designed to mass produce batteries and other key components for electric vehicles.

High-current connectors demonstrate their importance in supporting the efficient and reliable operation of the Giga Factory. Particularly in energy-intensive production processes. Helping the Giga factory achieve its goal of efficient and sustainable production.

Energy transfer during battery manufacturing:

Large amounts of electricity are required to power production equipment. Especially during the battery assembly and testing stages. High current connectors ensure efficient and stable power transfer from the factory’s power supply to the production equipment.

Automated Assembly Lines:

Highly automated assembly lines are commonly used in Giga plants to increase production efficiency. These automated systems, robots, and conveyor belts, require a steady supply of high currents to keep them running. High current connectors provide this power.

Energy management and distribution:

Giga factories require sophisticated energy management systems to monitor and distribute power. High current connectors are used to ensure that power is distributed efficiently between different production lines. And, are also used to connect to energy storage systems or emergency backup power sources within the Giga factory.

Testing and quality control of high current connector

Battery testing requires large amounts of power to simulate different usage and charging conditions. High current connectors are used to ensure that the test equipment receives the required current.

Power supply systems with renewable energy sources:

Many Giga factors use solar as a partial source of power. In this case, high current connectors are used to smoothly integrate these energies into the overall power supply of the Giga factory.

Future Trends of High Current Connectors

The high current connector is to transfer high current and high power. Widely used in industries, automobiles, aerospace, and new energy. For example, electric vehicle charging stations, as well as battery management systems. Industrial robots and aircraft electrical systems.

In the future, we possibly see high power density, miniaturization, intelligence, sustainability, and more standardization. All of them are for evolving applications of high current and high power.

The high power density of high current connector

Power densities continue to increase to meet the demand for higher power output. This will require greater design innovation and materials technology. Which is to ensure that high current connectors do not overheat or fail at high power.

Miniaturization and lightweight of high current connector

With the trend towards miniaturization and lightweighting of electronic equipment, high current connectors will also move towards being smaller and lighter. This will make them more suitable for compact applications and space-restricted environments.

High-frequency applications of high current connector

Wireless charging and high-speed data transmission require high-frequency current transmission. The high current connector needs to optimize the design to support high-frequency transmission.

Automation and intelligence of high current connector

With the development of industrial automation and intelligence, the high current connector may be integrated with remote monitoring, fault detection, and data transmission. It is to improve the efficiency and reliability of the system.

Sustainability and Eco-friendly of high current connector

Eco-friend and sustainability will also become very important for future high current connector design. Material selection and manufacturing processes may tend to be more eco-friendly to reduce the impact on the environment.

Standardization and interoperability of high current connector

To promote interoperability between different manufacturers, the industry may move towards more standardization. It is to ensure that different types of high current connectors can be seamlessly integrated into a variety of applications.

Technological innovation of high current connector

The future may emerge with new technological innovations. Such as more efficient conductive materials, more reliable connector design, and more advanced cooling technology. They will meet the changing high current transmission.

.

Conclusions