What Is a Test Fixture?

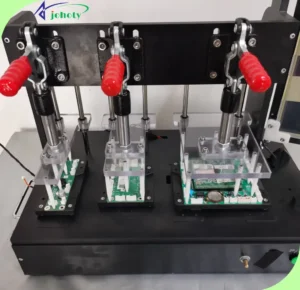

Test fixture profile

It is a customized test jig. The test fixture is designed to increase productivity, repeat specific actions, and make work more precise. It is a kind of jig that specializes in testing and experimenting with the function, power calibration, life, and performance of UUT. Because it is mainly used in the production lines for the testing of various indicators of the UUTs. So, we call it a test fixture.

Based on pogo pins in our company. We can provide you with all kinds of pogo pins in the onboard IC test fixture. ICT open and short test fixture. FCT function test fixture. Aging test fixture, and in burning-in test fixture.

Function Description

Including function test,

Contact resistance measurement,

Two-polar sensitivity test,

Insulation test,

Diode forward and reverse inspection,

Constant pressure test, and so on.

Precautions for use

First. After a test fixture is available, it is stored on the fixed frame in the fixture room. And stick a model identification on it.

Second. When finding broken or aging test probes in a test fixture. Please replace them with new Pogo pins or test probes. And continue to use the test fixture.

Third. When the test fixture is damaged and can’t be repaired well and used yet. If the customer will no longer use it yet, please apply for scrapping and re-production.

Fourth. The owner of the test fixture lab registers its use and asks to return it to the lab after use. And makes a good handover.

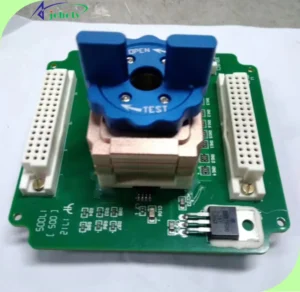

IC Test Socket/fixture

Profile

It is to test the electrical properties and electrical connections of IC chips. An auxiliary tool for checking manufacturing defects and bad components.

Test the packaged IC, which mainly consists of an interlocking top cover and a base.

The interior of the upper cover plate has through holes. And, lots of IC test probes are adjacent to these through holes for contacting the IC pads or pins.

Inner structure

The base has at least one support seat, corresponding to the through-hole of the upper cover plate. Which is for carrying the IC to be tested. There is at least one support spring between the lower part of the support seat and the base.

The distance between the through-hole and the support seat is less than the thickness of the IC chip. The elasticity coefficient of the support spring is greater than the sum of the elasticity coefficients of all IC Pogo Pins.

Benefits

It can prevent the IC UUT from being crushed due to the size difference.

Avoid test failure due to poor contact between the test socket and IC UUT.

To improve test yield and reduce manufacturing costs.

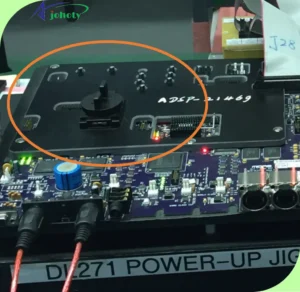

IC Onboard Test Socket/fixture

Profile

It is to test CPU, GPU, GCPU, or large IC chips else on the PCBA board. Which is different a bit from the IC test socket. In brief, it is to remove the large IC chip on PCBA first. Then, mount the IC onboard test socket onto the location of the large IC chip.

Finally, place the large IC chip into the socket and power it on for the test.

IC onboard test socket is helpful to quickly identify which ICs are good or bad. It can be continuously used as an IC onboard test fixture. When testing is complete, the PCBA can also throw away the fixture and restore it to a good product.

Inner structure

Fine pitch, plunger tips, barrel OD, and spring force are the top parameters in IC onboard test sockets. Their selection is all based on the IC pad specifications.

IC pogo pins are preferred. There are lots of shapes, including sharp, crown, round, cup, flat, dome, etc. Commonly, the fine pitch is ≥0.20mm. The spring force is ≥15gf. Barrel OD is ≥0.26. It is also okay to custom based on the customer’s requirements.

Features

Structure of manual flip-cover, easy to operate. And suitable for FBGA, MBGA, PBGA, UFBGA, and UBGA.

The IC platen of the upper cover adopts a spinning structure. The downward pressure is smooth and even. And, IC UUT does not shift and test stability.

The plunger tips of the IC Pogo Pins can pierce the oxidized layer of the solder ball. Firmly contact the solder ball without any damage to the solder ball.

Positioning slots, guide holes, and IC positioning have high test efficiency。

Can also test those IC chips mounted with tin beads.

Assembled with double-ended IC pogo pins or IC test probes. all plates are made of ESD anti-static material.

IC Pogo Pins and PCB contact IC’s solder pads or solder balls. Reusable, small size, long service life cycles.

IC test probes or IC pogo pins are easy to replace and maintain. RF is up to 6G, the pitch can be as low as 0.20mm.

Benefits

IC onboard test sockets can be used for IQC raw material inspection, repair inspection, and IC identification.

On the IQC station, it can quickly identify each defect, which can improve SMT pass yield. It is to run function programs by power on PCBA and ICT UUT. The solution is highly effective.

There is no way to tell if there was a problem with the PCBA during production. However, repair engineers can easily know whether the IC is the root cause of the problem. By putting the removed IC into the IC onboard test socket and testing it,

For those removed ICs, there is a possibility of damage during the removal process. An IC onboard test fixture can easily separate faulty ICs. It can save a lot of manpower and material resources, thereby reducing various costs

ICT/FCT Test Fixture

Profile

ICT/FCT test fixtures can test analog signals and digital signals of a UUT. it has a high failure coverage. Each UUT needs to make a special test probe holder, which we call it ICT or FCT test fixture.

Features of ICT/FCT Test Fixture

The ICT testing fixture has a single-sided and double-sided. Its upper frame is convenient for switching UUTs. And, the adjustable support seat is used for easy maintenance. It is made of acrylic, bake-lite, FR-4, or the specified. it generates drilling files directly by processing the Gerber files, and, ensures drilling accuracy.

it is better to make sure the pitch of 1.27mm or 2.54mm, between the two test points or the test point and the pre-drilled hole. The test points of the fixture should be distributed as evenly as possible. This ensures that UUT does not deform or dagame when to engage the ICT/FCT test fixture.

Function of ICT/FCT Test Fixture

ICT/FCT test fixture can check the electrical performance of UUT components and the connectivity of circuits.

It can quantitatively measure resistors, capacitors, inductors, crystals, and other components. Functional testing of diodes, transistors, optocouplers, transformers, relays, operational amplifiers, and power supply modules. Function test about small and medium-sized IC chips.

For defects in the manufacturing process and defective components, the test fixtures can detect them by testing the electrical performance of in-line UUT.

It can check if components are out of tolerance, failure, or damaged component values. Also, can detect errors in memory.

ICT/FCT test fixture can also detect process issues, including short, open, component insertion error, reverse, leakage, pin warping, false soldering, PCB short circuit, broken wires, and other faults.

The test fixture can accurately locate error components, component pins, and circuit points.

Benefits of ICT/FCT Test Fixture

It is the first testing process in production, which can timely reflect the production and manufacturing status, and is conducive to process improvement and enhancement,

With accurate fault location and convenient repair, it can significantly improve production efficiency and reduce repair costs,

Specific testing projects are important testing methods for ensuring the quality of modern large-scale production.

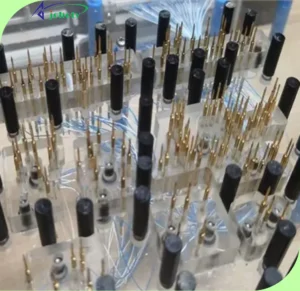

ICT Pogo Pins in ICT/FCT Test Fixture

Profile and Spec

ICT Pogo Pins are mainly used in the in-circuit test fixture and function test fixture. On ICT, they are to test PCBA by contacting test points on PCBA. And check if it is okay for electronic components and circuits connection on the PCBA board. On the FCT test, FCT Pogo Pins test the performance and reliability of UUTs. Under various operating conditions by simulating the actual use environment.

ICT Pogo Pins

It can quickly and accurately detect faults on circuit boards. Including short, open, and inaccurate resistance values.

- Efficiency: Can test multiple electronic components and circuit connections at the same time, greatly improving testing efficiency.

- Accuracy: Accurately detect defaults on PCBA by advanced testing technology. And greatly reduce the rate of misjudgment.

- Automation: ICT Pogo Pins can realize automated testing by working with ATE, reducing manual intervention, and improving test consistency and repeatability.

FCT Pogo Pins

It can simulate a variety of input and output signals of a UUT. Which is to test the response and performance of the UUT under normal operation and abnormal conditions.

- Overall: it can test various functional modules of a UUT. Including input/output interfaces, communication functions, power management, etc. it ensures the overall performance of the UUT.

- Reliability: it can simulate the use of the UUT in various working conditions. Detect the reliability and stability of the UUT. And detect potential problems in advance.

- Automation: it can realize automated testing and improve testing efficiency and consistency by working with ATE.

IC Pogo Pins in IC Test Socket and IC Onboard Test Socket

Profile and Spec

IC pogo pins, also known as IC test probes in the industry. Very precise with high craftsmanship requirements. Generally, it tests CPU, GPU, GCPU, mobile phone IC chips, laptop IC chips, tablet computers, communication IC chips, etc.

The barrel diameter of IC Pogo Pins is more than 0.26mm. The plunger tip diameter is more than 0.12mm. The stroke is more than 0.55mm. The length is more than 3.40mm. The rating voltage is usually 6V and 12V. The rating current is usually from 0.5A to 5.0A. The spring force is usually from 15gf to 300gf.

Shapes

The Plunger tips of IC Pogo Pins are common shapes with double ends. Further, it has double-ends double movement, and double-ends single movement. All shapes are based on actual applications.

- ball and ball,

- ball and dome,

- ball and flat,

- ball and sharp,

- crown and ball,

- crown and crown,

- crown and dome,

- crown and flat,

- crown and sharp,

- cup and sharp,

- dome and sharp,

- Flat and Flat,

- sharp and flat,

- sharp and sharp.

Conclusions

This article detailedly introduces a test fixture, IC test socket, and IC onboard test socket. ICT/FCT test fixture, as well as the IC test pins used in the test fixture. Discusses their characteristics, structure, functions, benefits, and more of test pins.

We hope to contribute to your electronic design and testing work. If they are unclear or you plan to order various test probes, pogo pins, or fixtures. Please timely contact us, We will fully support you and be very happy to serve you.